We are here to help.Easy ways to get the answers you need.

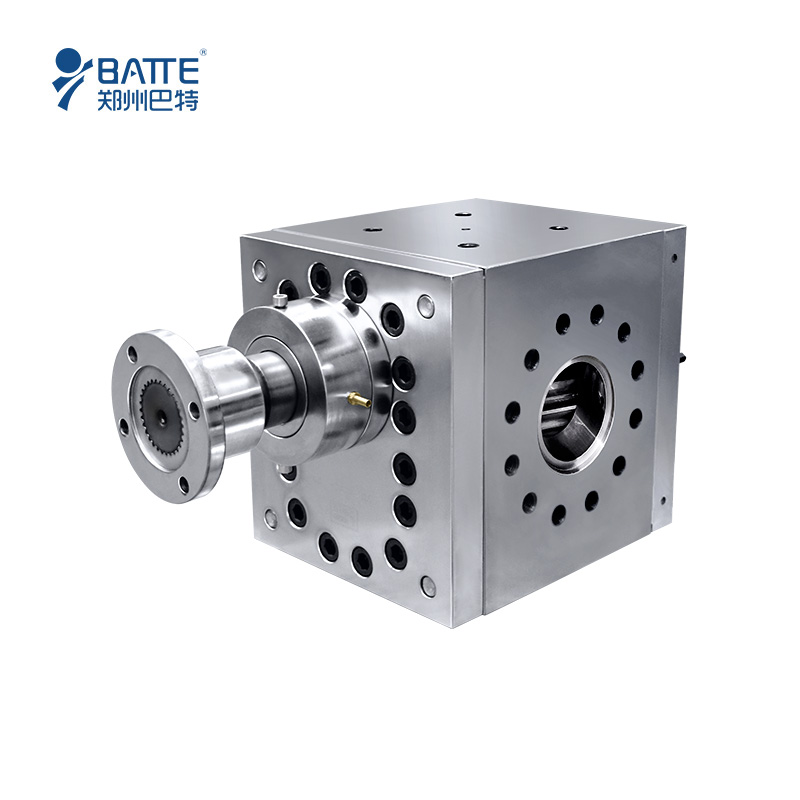

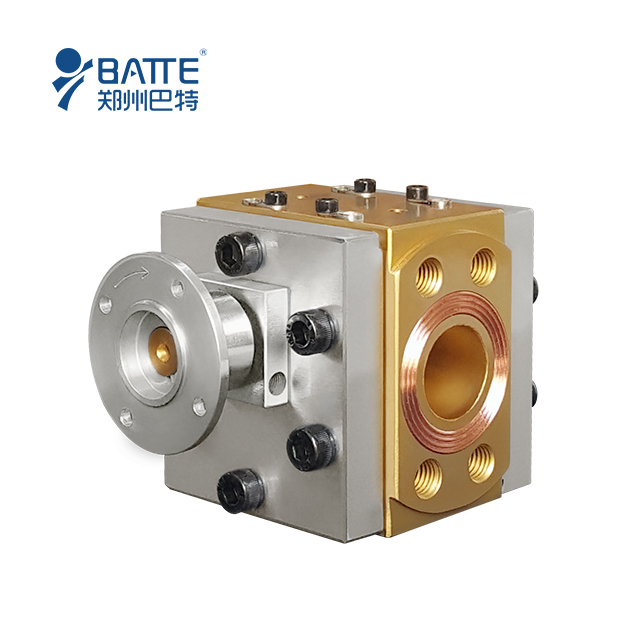

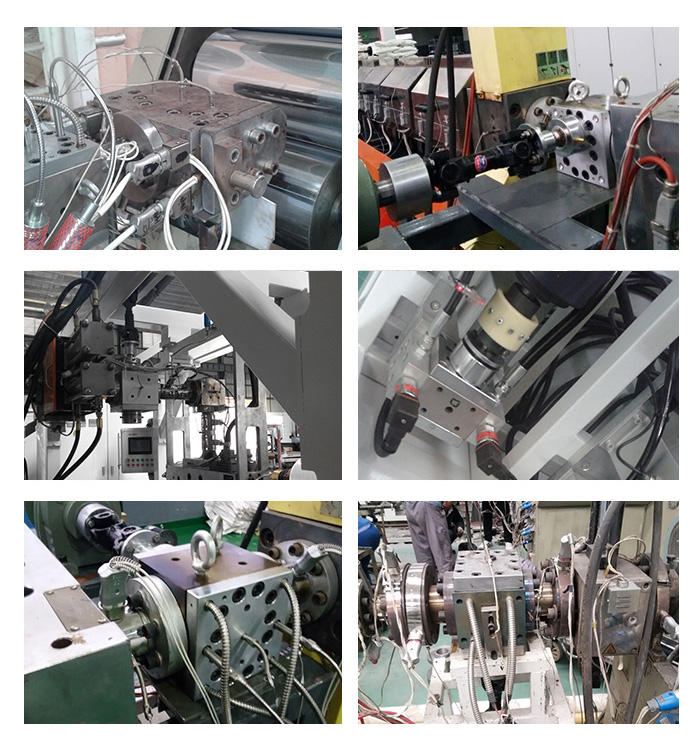

Booster melt pump means the pump has the function of boosting pressure to polymer melt. Booster pumps are Batte hot products and widely used in related factories. Booster melt pump is used for transportation, pressurization or the metering of the high temperature and high viscosity polymer melt. Booster melt pumps are used in the polymerisation process, to boost the pressure of medium to high viscosity media.

Booster Melt Pump Features:

certificate

Place of Origin: Henan, China (Mainland)

Brand Name: Batte

Model Number: ZB-B, ZB-C, ZB-D, ZB-E, ZB-F, ZB-G, ZB-H, ZB-K, ZB-R

Theory: Positive Displacement Gear Pump

Structure: Gear Pump

Usage: Plastic, Rubber Pump and Fiber

Power: Electric or Oil

Fuel: No Need

Pressure: High Pressure

Application: transportation, pressurization or the metering of polymer

Scope of Application: Almost all kinds of polymers(plastic, rubber, chemical fiber...)

Viscosity: Up to 40000Pas

Gear Tooth: Straight (Optional), Helical gear pump(Optional), Herringbone gear pump(Optional)

Sealing Method: Mechanical Sealing (Optional)

Heating Method: Stainless Steel Heating Rod

|

Packaging Details: |

Items are packed in wooden cases. |

|---|---|

|

Delivery Detail: |

5-6 Weeks |

Zhengzhou Batte Melt Pump Co., Ltd. is a professional manufacturer of melt pumps, screen changers and feeders integrating R&D and production. Located in the University Science and Technology Park of Zhengzhou High-tech Industrial Development Zone, it relies on the scientific research strength of domestic universities and combines European advanced technology and quality control concepts to integrate production, learning and research. Especially in the application technology of melt pump, has accumulated rich experience. Continuous in-depth research on the working principle, performance optimization, equipment structure optimization, control technology and other aspects of the melt pump has achieved considerable results, and has been recognized and praised by the vast majority of users in the industry. info@battemachinery.com