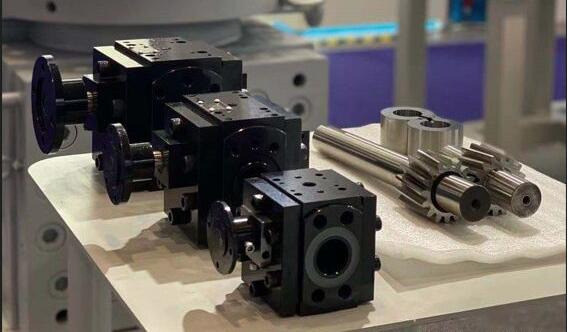

Bearing is one of the core components of melt metering pump. Materials and designs must be carefully selected and coordinated to ensure safe and efficient operation of metering pumps.

The melt self lubrication is adopted for the shaft and shaft sleeve of the melt pump, which is realized through the leakage design from the pump outlet end to the suction end and through the whole bearing. The flow of polymer melt is very necessary to protect the bearing. This flow requires that the outlet pressure and inlet pressure of the pump should not be the same. It is recommended that the pressure difference between the two ports should be kept at several hundred psi.

Since the bearing of the melt pump is lubricated by melt, the outer surface of the bearing needs to be sealed to prevent the polymer from flowing to the outer surface of the gear shaft. In order to adapt to different melt viscosities and pump pressures, most melt pumps are equipped with water-cooled seals. This requires a reasonable adjustment of the amount of water to ensure that there is enough water to prevent leakage or reduce the leakage to a micro level. However, the amount of water should not be too much, as this will reduce the lubrication effect of the shaft and increase the load on the melt pump motor.

Friction bearings are commonly used in melt metering gear pumps. For this bearing type, the inner diameter is slightly larger than the journal stored therein. The conveyed medium penetrates into this small area through the lubrication groove. Through the lubrication groove, the medium in the bearing forms a hydrodynamic lubrication film. The shaft "floats" in the bearing. For friction bearings lubricated with medium, the lubricating film must not be torn. Otherwise, the shaft will not be able to re lubricate and cause damage to the shaft and bearing. This damage is usually irreparable, resulting in the need to replace bearings and shafts. info@battemachinery.com

pre:What are the improvements of the pulseless melt pump of the extruder?

next: Structure and parameters of melt high-pressure pipeline booster pump for polymer process