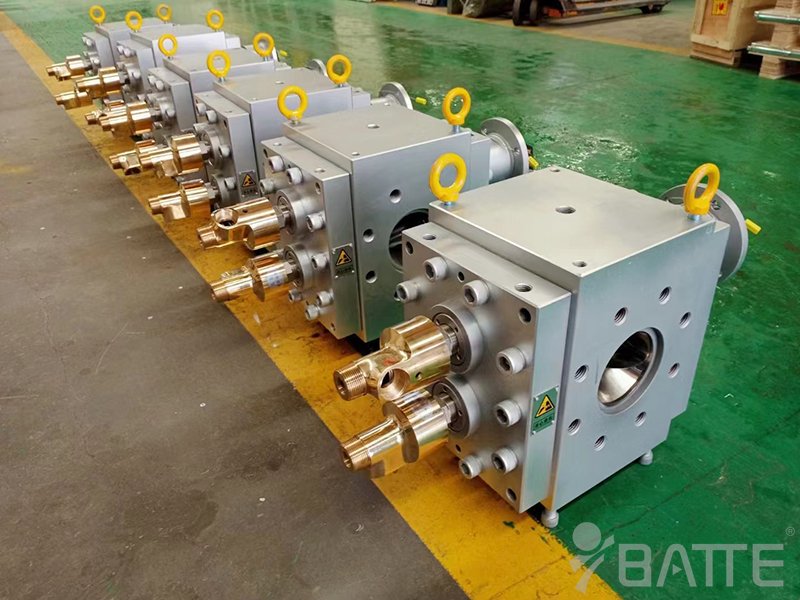

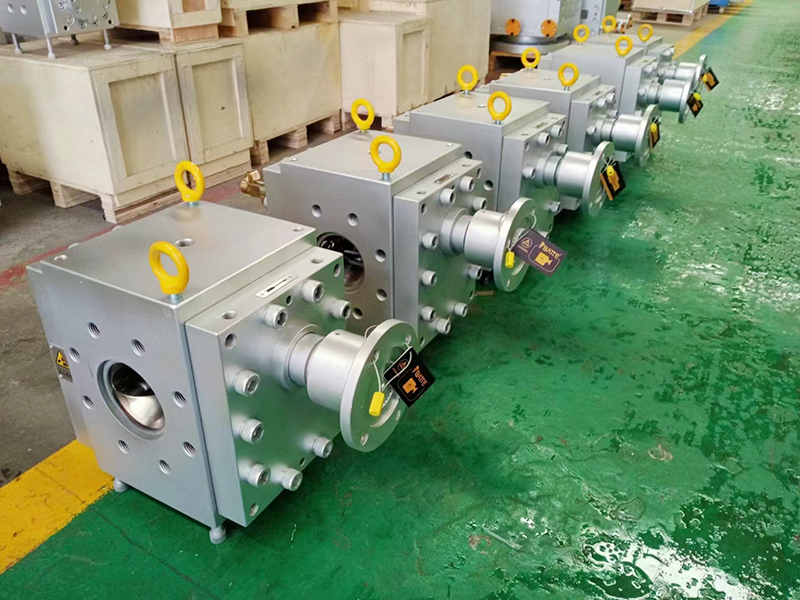

In view of the special working conditions of the melt pump used in the EVA photovoltaic film extrusion production line, Zhengzhou Batte independently developed and produced the melt pump for EVA photovoltaic film, which has the functions of high-precision metering, pressure stabilization and pressurization.

characteristic:

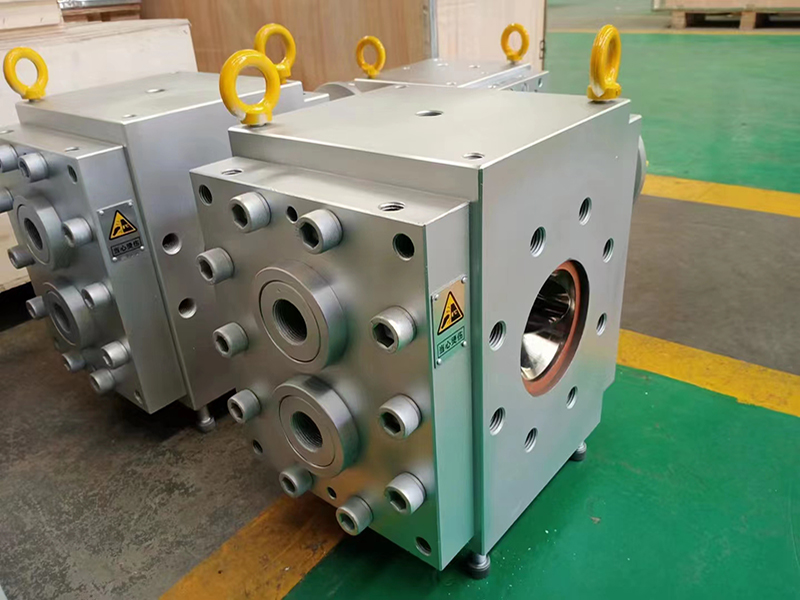

1. The temperature control is electric heating + circulating water temperature regulation.

EVA modified adhesive resin must have sufficient time to activate anhydride during coextrusion to ensure sufficient adhesive force. Therefore, the setting of temperature is very important. In order to prevent EVA from degrading due to excessive processing temperature, the processing temperature should be limited to 238 degrees. The EVA film melt pump is internally designed with circulating temperature control water for temperature regulation.

2. The design of flow channel has no dead angle, and the internal circulation flow channel has smooth arc transition.

Too high temperature or dead angle during extrusion will cause EVA resin to stay for too long, which may cause resin aging. Therefore, the retention time will also affect the quality of the film. The design concept of the melt gear pump for EVA film is the same as that of the rubber melt gear pump. There is no dead angle inside, and the circulation lubrication flow path is uniform and smooth.

3. Temperature control circulating water of gear shaft.

When the gear is engaged to transport the resin compound, it will generate shear heat. In order to avoid the temperature rising too fast, the axis of the EVA film melt gear pump is designed with circulating temperature control water, and the shaft head is equipped with a rotary joint.

4. Adopt helical tooth design.

The gear of EVA film melt gear pump adopts helical gear meshing, and the meshing operation is stable. The production capacity is increased and the shearing effect is reduced.

5. The seal is maintenance free spiral seal.

The EVA film melt pump adopts the spiral seal form, which avoids the influence of the residue of the conventional packing seal on the product.

Zhengzhou Batte is a professional manufacturer of melt gear pumps, providing a variety of specifications of melt gear pumps for the resin, chemical fiber, rubber and other polymer material industries, and providing a variety of series of melt gear pump products that can meet all polymer working conditions. The company provides melt gear pumps with complete specifications: from 0.1cc to 12000cc, or non-standard customization according to user needs. info@battemachinery.com

pre:Maintenance and parts supply of imported melt pump

next: Why do high-temperature melt pumps choose gears with small axial force?