I. Preparation Before Installation

Inspection and Confirmation:

Carefully unpack the melt pump and thoroughly inspect the pump body and all components for any damage or missing parts. If any issues are found, immediately contact the supplier or manufacturer. Confirm the installation location of the pump, ensuring it can accommodate the pump's size and weight and facilitate the connection of feed and discharge pipes.

Preparation of Installation Foundation:

Prepare a sturdy foundation at the selected installation location to ensure stable installation of the melt pump. The foundation can be made of materials such as concrete or steel plate, designed according to the pump's dimensions and weight.

II. Installation Steps

Connecting Pipes:

Connect the feed and discharge pipes as needed, ensuring they match the inlet and outlet of the melt pump and are securely fastened to prevent leaks.

Installing Support Frames or Platforms:

Depending on the type and size of the melt pump, support frames or platforms may be required. These devices provide additional support and stability, ensuring safe operation of the pump.

Installing Motor and Drive Unit:

If the melt pump is driven by a motor, install the motor in a suitable location and ensure it is correctly connected to the pump's shaft. Ensure the motor and drive unit can provide the required rotational speed and power.

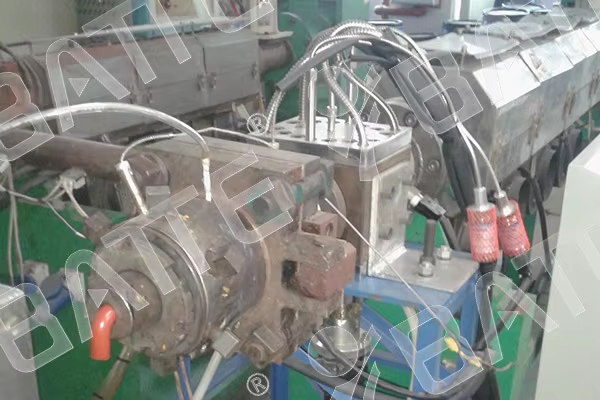

Connecting Sensors:

The melt pump body and exterior usually have holes for pressure sensors and temperature sensors, which should be correctly installed to ensure accurate measurement data.

Inspection and Debugging:

After installation, perform necessary inspections and debugging. Ensure all components are installed correctly and check that the pipe connections are secure and leak-free. Verify the pump's normal operation, including the correct rotation direction.

III. Startup and Operation

Preparation Before Startup:

Before starting the melt pump, ensure all pipes are flushed clean, and valves and control instruments are functional. Also, check if the pump chamber has been filled with sufficient medium to be transported.

Startup and Low-Speed Operation:

Start the melt pump at a low speed. Once the pump operates stably, gradually adjust to the normal rotational speed and pressure.

Monitoring and Adjustment:

During the operation of the melt pump, regularly monitor its status, including temperature, vibration, and noise levels. If any abnormalities are found, immediately stop the pump, investigate the cause, and take appropriate measures for adjustment or repair.

IV. Shutdown and Maintenance

Shutdown Procedure:

To stop the pump, first disconnect the motor power supply, then stop the pump. Close the gate valves on the inlet and outlet pipes.

Maintenance:

Regularly maintain the melt pump, including cleaning, lubrication, and replacing wearable parts. This helps ensure normal operation and extends the pump's lifespan.

V. Precautions

Safe Operation:

When using the melt pump, follow relevant safety operating procedures. For example, when inspecting or repairing the pump, first cut off the power supply and take appropriate safety measures.

Troubleshooting:

If the melt pump malfunctions or operates abnormally during operation, immediately stop the pump and identify the cause. Do not attempt to force the pump to operate or perform improper repairs.

Training and Guidance:

Provide necessary training and guidance to personnel using the melt pump for the first time. This helps them familiarize themselves with the pump's structure, working principle, and operating methods, ensuring they can use the melt pump correctly and safely.

In summary, the use of plastic extrusion melt pumps for wire and cable production requires following specific steps and precautions. Proper installation, startup, operation, shutdown, and regular maintenance are crucial for ensuring the normal operation of the melt pump and extending its lifespan.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:What are the disadvantages of applying melt pumps in woven bag production?

next: Application scenarios of wire and cable melt gear pump