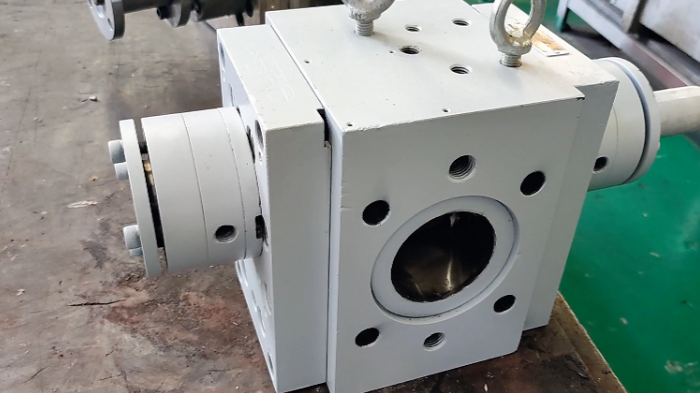

Double-ended sealed melt pumps are suitable for various situations requiring high temperature and pressure, high sealing performance, and long service life. Below are specific application fields and scenarios:

Plastic Processing Industry

Polymer Melt Transfer: In plastic extrusion, injection molding, and other production processes, double-ended sealed melt pumps can stably transfer high-temperature and high-pressure polymer melts, such as polyethylene and polypropylene.

Mixing, Extrusion, and Granulation: Combining a co-rotating twin-screw extruder with a melt pump into a mixing, extrusion, and granulation production line can significantly improve mixing quality and output while reducing energy consumption.

Chemical Industry

Corrosive Media Transfer: In chemical production, double-ended sealed melt pumps can be used to transfer various corrosive media, such as strong acids and bases, ensuring the safety and environmental protection of the production process.

Handling Flammable and Explosive Media: Due to their high sealing performance, double-ended sealed melt pumps are also suitable for handling flammable and explosive media, ensuring the safety of the production process.

Pharmaceutical and Food Industries

High-Temperature and High-Pressure Pharmaceutical Material Transfer: In pharmaceutical production, double-ended sealed melt pumps can be used to transfer high-temperature and high-pressure pharmaceutical raw materials, ensuring drug quality and safety.

Food Raw Material Processing: Similarly, they can also be used for the transfer and processing of food raw materials, ensuring food hygiene and quality.

Other Fields

Oilfield Water Injection Pumps: In oil extraction processes, double-ended sealed melt pumps can be used to inject high-pressure water into oil wells to drive crude oil up. Their wear resistance and corrosion resistance can meet the demands of continuous operation for long periods.

High-Temperature and High-Pressure Pump Applications: In high-temperature and high-pressure environments in industries such as power generation and metallurgy, double-ended sealed melt pumps can maintain stable sealing performance, ensuring the normal operation of the pumps.

In summary, due to their characteristics of high temperature and pressure resistance, high sealing performance, and long service life, double-ended sealed melt pumps have a wide range of applications in multiple fields. During use, it is important to ensure the concentricity of the pump base and motor drive shaft, regularly check the integrity of sealing components, and regularly maintain and service the pump body to ensure its normal operation and extend its service life.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:What is the scope of application for rubber extrusion melt pumps?

next: What are the application scenarios of chemical melt transfer pumps?