We are here to help.Easy ways to get the answers you need.

Meltblown fabric is made of polypropylene as the main raw material, and the fiber diameter can reach 0.5-10 microns. These ultra-fine fibers with unique capillary structure increase the number and surface area of fibers per unit area, thus making meltblown fabric with good air filtration, which is the core material of medical masks and plays an irreplaceable role in medical and health, home decoration, industry, agriculture, and other industries. To produce qualified non-woven fabric, the choice of machine is crucial. The good or bad of a machine does not lie in the size or price of the machine, but in whether the machine can run stably and accurately. As long as the machine can run stably and precisely, 50 and 55 machines can also produce 95 or even 99 grade cloth.

PP Single Secrew Extruder Melt Blown Mask Machine

With nearly 20 years of professional production experience, Batte offers better solutions according to the production principle of nonwovens, common materials, process characteristics, heating temperature, processing pressure and output.

Single S Spunbond Non Woven Cloth Extrusion Production Line

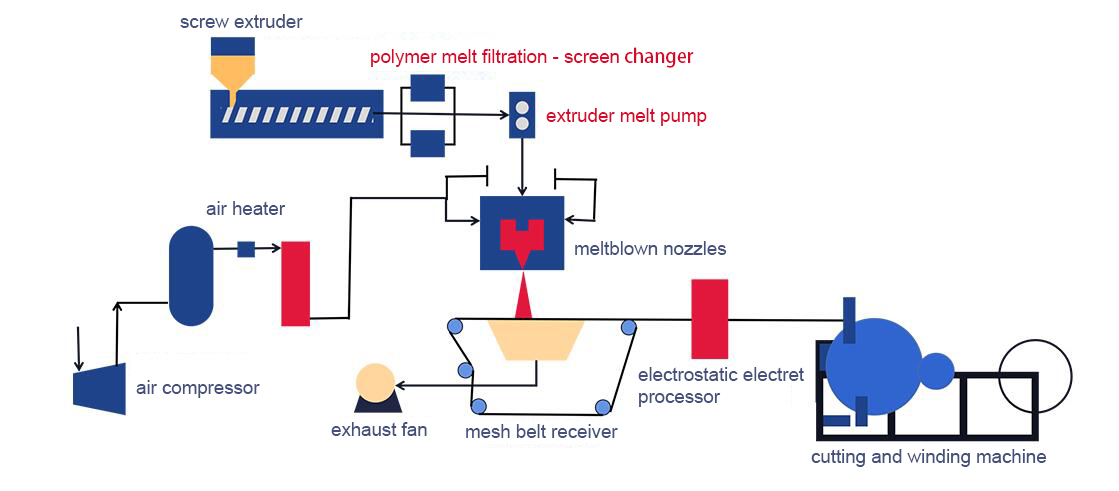

Meltblown method is a method of preparing fibers by relying on high temperature and high speed airflow to blow the polymer melt so that it gets stretched rapidly. The polymer chips are heated and pressurized into a molten state by a screw extruder, and then reach the spinnerets at the front of the nozzle through the melt distribution flow channel, and are extruded and then refined by the stretching of two converging high-speed, high-temperature air streams. The refined fibers are cooled and cured on the net curtain device to form meltblown nonwoven fabric.

Double S Spunbond Nonwovens Production Line

The production process of meltblown fabric is divided into: polymer preparation → melt extrusion → metering pump → meltblown die assembly → melt fine stream stretching → cooling → receiving device.

As a professional company providing meltblown production line equipment, in response to the internal demand for meltblown fabric production equipment, Zhengzhou Bart developed the specific standard configuration of meltblown PP metering pump and meltblown screen changer for use in meltblown production line in mid-February 2020 to meet the demand for meltblown fabric production of different widths.

| Configuration standards of PP metering melt pump + melt filter screen changer for meltblown fabric production line | ||||

| Screw specifications | Capacity | Meltblown fabric width | Melt pump model | Melt Filter model |

| Φ45 | 10-20kg/h | 600mm | ZB-M-10CC | ZB-2MR-100 |

| Φ65 | 20-60kg/h | 1200mm | ZB-M-20CC | ZB-2MR-120 |

| Φ90 | 60-100kg/h | 1600mm | ZB-M-30CC | ZB-2MR-150 |

| Φ105 | 80-150kg/h | 2400mm | ZB-M-50CC | ZB-2MR-175 |

| Φ120 | 150-200kg/h | 3200mm | ZB-M-100CC | ZB-2MR-195 |

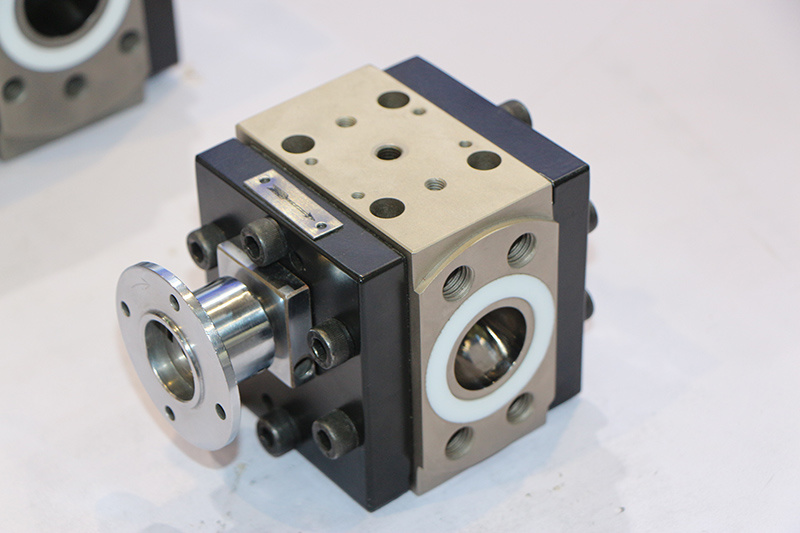

The specific model of meltblown PP metering pump provided by Zhengzhou Batte is ZB-M series, and the model of meltblown screen changer provided is ZB-2MR series, which is suitable for the production of meltblown fabric width of 600mm, 1200mm, 1600mm, 2400mm and 3200mm. the pump body of meltblown metering pump adopts high temperature tool steel, the heating system adopts electric heating, and the seal adopts screw seal plus shaft end Water cooling. The meltblown screen changer is made of special alloy material through strict forging, surface heat treatment and precise metal processing process; Zhengzhou Batte adopts high quality heat treatment process and strict quality control system to ensure the stability and durability of meltblown screen changer use.

melt blown melt gear pump

polymer melt filter screen changer for PP melt blown extruder

Over the past decades, Zhengzhou Batte has focused on the development and manufacture of integrated solutions for screen changers and melt metering pumps for the plastics, chemical fiber, nonwoven and chemical industries. In recent years, Zhengzhou Batte has provided a large number of customized meltblown metering pumps for domestic nonwoven equipment manufacturers, which have the advantages of no pulsation, accurate metering and long life. Please consult us at info@battemachinery.com for details on how to configure the meltblown fabric production line equipment.