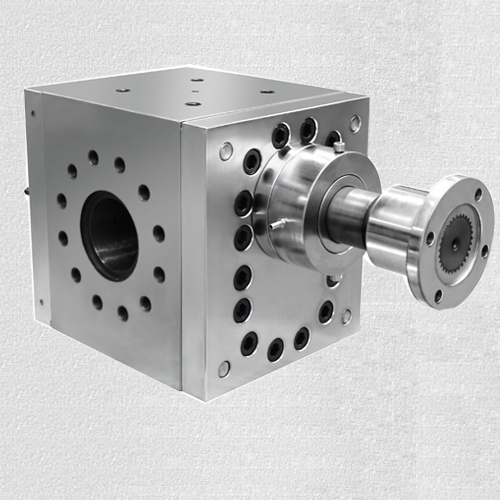

In the design process of plastic melt gear pump, the following eight aspects need to be considered in order to ensure that the designed melt gear pump has stable performance, durability and long service life.

1. The gear profile of the plastic melt gear pump should adopt the involute money gear with a precision of more than seven grades. The flatness and parallelism of the two ends of the gear are required to be very high. 2. The gears and bearings of the plastic melt pump are located in the middle plate together, which can reduce the deformation checking and position difference caused by the rising temperature in use, so as to prevent the sticking or jamming of the melt pump. 3. The choice of the radial clearance and end clearance between the gear and the middle plate of the plastic melt pump should not only ensure that the pump has a higher volume efficiency, but also ensure that the pump is not stuck at high temperature.

4. For the internal structure of the plastic melt pump, such as the middle plate, the inner cover plate and the outer cover plate, the accuracy of flatness and parallelism is required to be high, so as to play a sealing role. 5. When the gear of the melt pump rotates, the melt is used for self-lubrication. There are grooves between the shaft and the bearing to introduce the melt from the melt inlet for compulsory lubrication. 6. Packing is used to seal the joint of the driving shaft and the hole of the outer cover plate. The material is PTFE with high temperature resistance, in which graphite powder is added to improve the lubrication performance. 7. The plastic melt pump developed and manufactured by Bart is made of tool steel with good hardness and small deformation. The hardness of heat treatment should be high in order to improve the strength and service life. 8. The strength of the flat key has to be calculated. It can protect the gear when the melt gear pump runs unexpectedly.

pre:What are the advantages of electric heating kettle bottom pump?