Extrusion melt pumps are commonly used for the precise transfer and metering of polymers, fuels and chemical additives. In extrusion pump applications, melt pumps stabilize the process by generating a constant pressure, ensuring a constant flow of material and relieving the pump extruder from the pressure build-up task.

Even when high viscosity rubber is extruded, an increase in extrusion pressure at the outlet die part will not change specific output quantity, nor will it increase output rubber temperature by any significant amount. The melt pump pressurizes and stabilizes pressure of hot melt polymers coming from the extruder, then send into extruder dies.

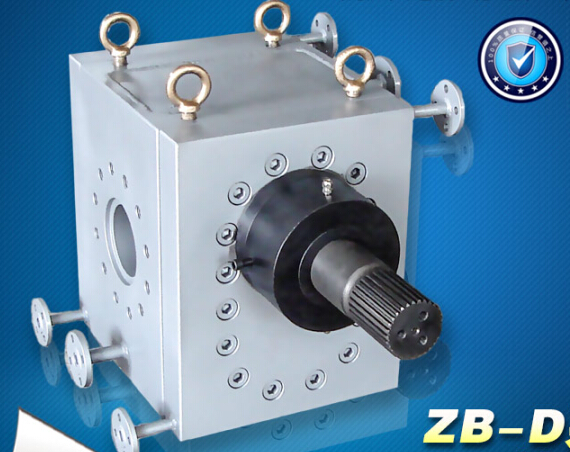

Batte melt pump features:

Melt pump belong to positive displacement gear pump,adopt a pair of external gearing cylindrical gears with relative turning to deliver high viscosity fluid. All gears and fitting surfaces are accurate grinded,and obtain precision flow by controlling the assembling clearance strictly.

Batte pumps Can fall into the categories:ZB-B series,ZB-C series,ZB-H series,ZB-E series.