How to Select the Right Pump for Your Chemical Application

Chemical pumpsare defined as those with the application of making, using or disposing of chemicals. They are designed and constructed out of materials that can withstand substances with varying levels of viscosity, corrosiveness, and abrasiveness. Some chemical pumps are also metering pumps, which provide flow measurement and control for applications that require precise volumes of chemicals.

Chemical pumps have applications in many different industries, from general industrial applications to oil and gas, brewery and distillery, semiconductor and others. The following chart indicates the industries for more than 12,000 users of the IEEE GlobalSpec parametric SpecSearch®filter for chemical pumps from 2012 to 2016.

Selecting the correctchemical pumpinvolves many variables. Pump handbooks and specialty software can aid in pump specification. Chemical MSDS and compatibility data may be required as well. The first step in chemical pump selection is a proper understanding of the application requirements and the chemical media properties along with selecting the pump with the specifications to perform the task. The following graphic lists some of the main criteria to consider during chemical pump selection.

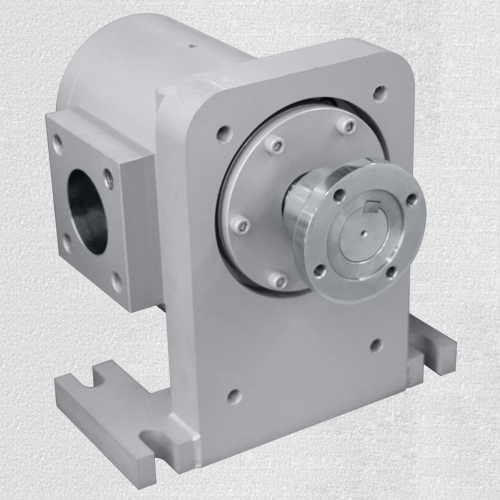

Our positive displacement pumps are designed to handle difficult, abrasive, corrosive and gaseous fluids. The only part to come into contact with the product is the tube or hose. This means there are no seals or valves that can wear or fail. Replacing the tube or hose can be performed quickly and safely.

Continuous dry running and self-priming eliminates the risk of gas locking or blockage. Precise metering of flow rates from microlitres per minute to 80 cubic metres per hour, with consistent accuracy of up to ± 0.5% ensures economical use of expensive chemicals and optimised system performance.

pre:A gravimetric feeder measures the flow's weight and adjusts the feeder output to maintain