The use of a single-screw pump extruder in series with a melt pump is a major area of application for melt-pump extrusion technology. Abroad more known as the melt pump auxiliary extrusion, the melt pump on the subordinate secondary status. In China, it is generally believed that only when using single screw Received date: 2003004Ο10 P1, P2, P3, respectively, different parts of the melt pressure sensor. Schematic diagram of the SP system extruder rod extruder does not reach the squeeze It is necessary to use it only when the tolerance of the product is required. That is, as the series melt pump is only to increase the role of measurement. This article defines this combination currently used in the extrusion field as a "single-screw-melt pump tandem extrusion system" or "Single2screw" for short. Also known as "single screw - melt pump series extrusion unit", or simply "SP unit." Proposed this concept, intended to emphasize the pump and screw combination of the overall and functional complementarity, complement each other and form a new extrusion system. Therefore, from the overall SP system to analyze and evaluate its performance, an objective and comprehensive understanding of its excellence, so as to further tap the potential of single-screw extruder to play the advantages of melt-extrusion technology.

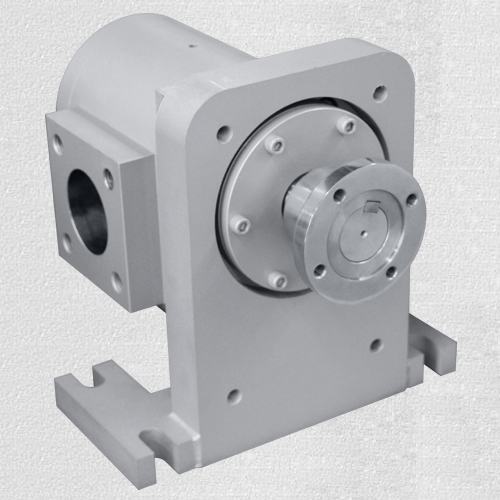

I recently developed a small SP unit, the main equipment technical parameters are: screw diameter 32mm, aspect ratio 28, the pump displacement 10cm3 / transfer, referred to as SP32210. The following, combined with our design

Mentality, experimental work and related literature, detailed SP system causes, performance and application.

pre:melt pump suction pressure

next: How to control the temperature of high temperature melt gear pump