plastic sheet extruder production line, PLC control parameter setting, data computing, alarm and other functions of the automation and control. Using different screw design and mechanical configuration, to achieve product width, thickness adjustable. Applicable to PVC, PET, PS, PP, PC and other plastic sheet production. Apply to the transport of decorative panels, non-slip mats, food industry, hospital industry with non-toxic plastic sheet. In the industrial, commercial, construction and other plastic sheets have also been widely used.

Raw material pre-crystallization treatment;

--- The material is heated by an extruder, conveying, compression;

--- Material through the dispersion and mixing, the solution homogenization, and then a stable pressure input filter and flat extrusion die;

--- Solution filtration;

--- homogeneous homogeneous pump out of the pump;

--- Co-extrusion homogeneous distribution stratified;

--- Melt in the die evenly shunt, quantitative and stable extrusion;

--- Die forming;

--- Three roller Cooling, setting;

--- Cut waste edge to the required width size;

--- Natural cooling conveying sheet;

--- Hand roll waste;

--- Stable traction sheet;

Place of Origin: Henan, China (Mainland)

Brand Name: Batte

Model Number: ZB-B, ZB-C, ZB-D, ZB-E, ZB-F, ZB-G, ZB-H, ZB-K, ZB-R

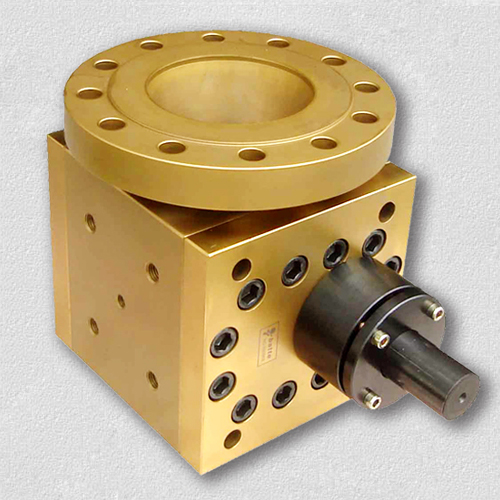

Theory: Positive Displacement Gear Pump

Structure: Gear Pump

Usage: Plastic, Rubber Pump and Fiber

Power: Electric or Oil

Fuel: No Need

Pressure: High Pressure

Application: transportation, pressurization or the metering of polymer

Scope of Application: Almost all kinds of polymers(plastic, rubber, chemical fiber...)

Viscosity: Up to 40000Pas

Gear Tooth: Straight (Optional), Helical gear pump(Optional), Herringbone gear pump(Optional)

Sealing Method: Mechanical Sealing (Optional)

Heating Method: Stainless Steel Heating Rod