1. Carefully check the packaging of the melt pump. If there is any damage or missing parts, please contact our company immediately. This melt pump is made of high temperature alloy steel material. All the parts are treated with high heat treatment hardness, so the material is more delicate. Any collision or collision can cause serious damage and is recommended to be mounted with a sling.

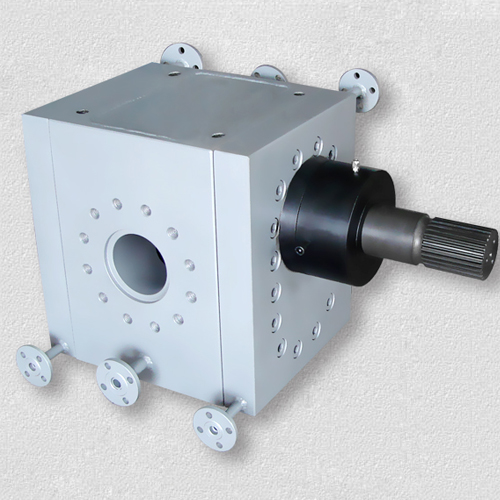

2. Please accurately judge the inlet and outlet of the melt pump when installing. The shaft of the melt pump is clockwise when the installation is correct. Installation of motor, reducer, universal couplings and pump, the pump must be installed base fixed, ensure the pump and motor shaft concentricity, turns must be free of binding, otherwise will cause gear block, serious when the shaft fracture.

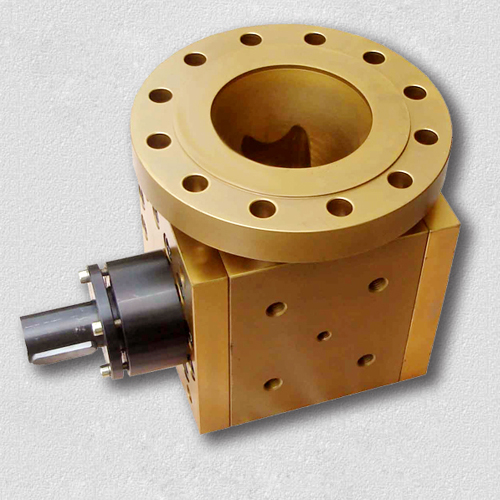

3. The surface of the melt pump body is equipped with pressure sensor hole and temperature sensor hole, because the sensor is installed correctly, otherwise the measurement data will be deviated. High strength (12, 9) bolt connection is used to ensure the safe operation of pump body.

4. When starting the melt pump, it should operate at low speed. When the melt pump is stable, it can be adjusted to normal speed and pressure. If the pump is not smooth, it must stop the pump to check the cause, so as to avoid serious damage inside the melt pump. If the packing seal is adopted, the sealing position is always adjusted so that the sealing state is always in the best position.