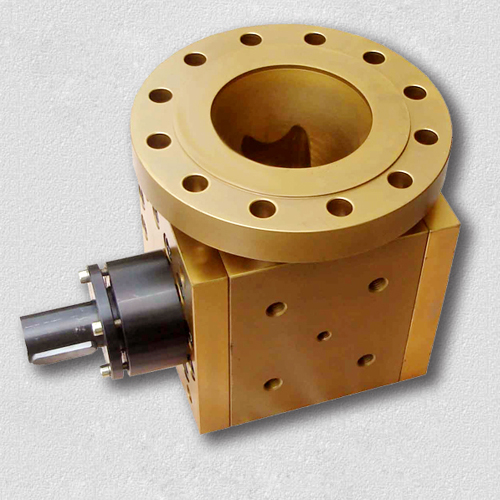

Zhengzhou Batte provides a new generation of gear pump. When the gear pump shaft rotates, the cryogenic liquid is sucked into the bearing through the screw action and the pressure difference between the two ends of the bearing, and then flows into the newly disengaged teeth, forming a fully lubricated, fast cooling system. Self-priming low pressure lubrication system.

The gear pump above-mentioned lubrication method has its own advantages: the bearing lubricating fluid that enters the gear pump is low-temperature, and it is easy to form a dynamic pressure oil film with strong bearing capacity; through continuous circulation of a large amount of lubricating fluid, it takes away the heat of the gear pump bearing, and is well lubricated. Cool the bearing. As there is sufficient liquid to fill the roots of the gears just disengaged from the meshing, the self-priming performance of the gear pump is greatly improved, the phenomenon of vacuuming is avoided, the volumetric efficiency is improved, and the cavitation erosion and the humming noise are also reduced. Zhengzhou Bart gear pump manufacturers to provide a new generation of gear pumps, the bearing material of tool steel and surface hardening treatment to improve its anti-gluing ability. If the conveying medium contains abrasive particles, a very hard bearing material (such as ceramics) is used, and its wear resistance and anti-adhesiveness are superior to those of the soft bearing material.

pre:Gear pump bearing materials

next: Polyester Melt Gear Pumps Extend Service Life Measures