Someone can tell me why the melt pump outlet pressure of the extruder decreases (year by year), and the new melt pump does not work. How can this be changed?

One or more of the following factors may simultaneously contribute to the decrease of the outlet pressure of centrifugal pumps:

1. The working point shifts to large flow rate and low lift. Generally, centrifugal pumps have continuous downward performance, and the flow rate increases gradually with the decrease of head. In the actual operation process, due to some reason, the back pressure of the pump decreases, and the working point of the pump passively shifts to the low-head and large-flow point along with the device curve, which will result in the decrease of the lift. In fact, this is caused by external factors such as the change of the device, which has no special relationship with the pump itself. At this time, as long as the back pressure of the pump is increased, such as the outlet valve of the closing point, it can be solved.

2. Motor inversion: Because of wiring causes motor inversion, it is generally necessary to check whether the pump's steering is correct before starting. If inversion occurs, any two wires will be exchanged for service.

3. Speed reduction: Impeller diameter and pump speed are important factors affecting pump head. Under other conditions unchanged, pump head and speed are proportional to the quadratic equation. It can be seen that speed has a great impact on the head, so the reduction of melt pump speed will greatly affect the long-term head.

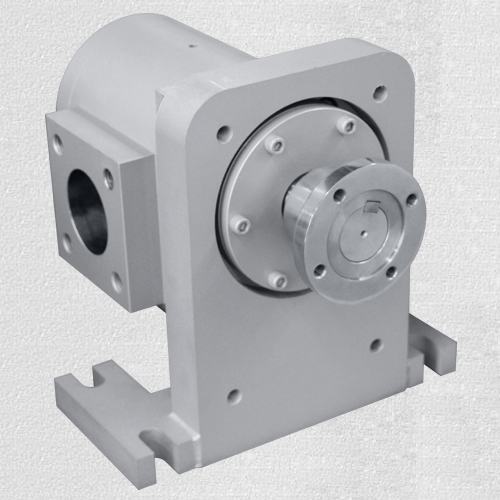

pre:Structure and Working Principle of High Temperature Gear Pump