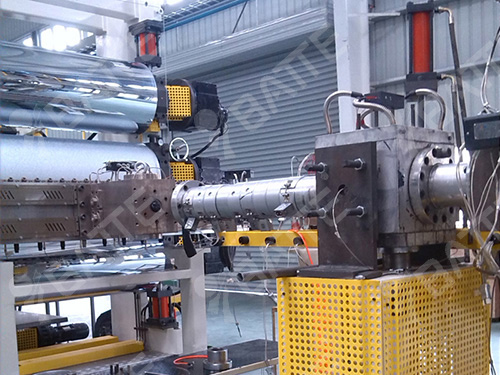

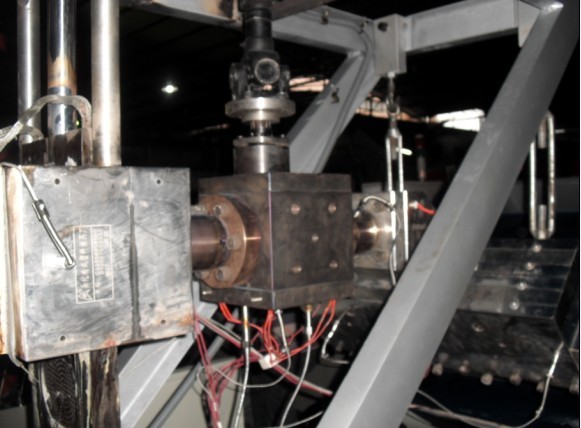

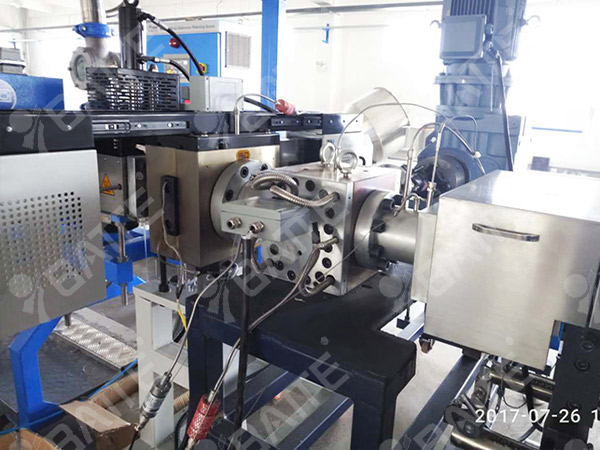

The melt pump provides the pressure between the extruder and the mold, and can match the parameters of the extruder to provide uniform melt with increased output and strict tolerance requirements. It is generally installed between the outlet of the extruder and the head, and is widely used in polymer extrusion molding such as granulation, film, pipe, plate, sheet, etc. It can also be installed in the pipeline to transport high-viscosity pure materials.

Butter melt pump is a positive-displacement conveying equipment with high-precision gear clearance and volumetric structure design, which makes stable and balanced extrusion possible. It has been widely used in production lines such as chemical fiber, granulation, plastic film, sheet, plate, profile, pipe, wire and cable, wire drawing, composite extrusion, etc., and has achieved relatively good results:

Increase production, reduce energy consumption, realize low-temperature extrusion and extend the service life of the machine. Because the extruder is installed with a polymer melt pump, the pressure reduction function of the extruder is transferred to the gear pump to complete. The extruder can work at low pressure and low temperature, with a greatly reduced leakage flow and increased output. The gear pump can more easily and effectively establish the head pressure than the extruder, reduce the back pressure of the extruder, reduce the axial force borne by the screw, and extend the service life.

With linear extrusion characteristics, it is convenient for upstream and downstream equipment to work in coordination. Because the leakage flow of the gear pump is small, the delivery capacity of the pump is basically linear with the rotation speed. After the rotation speed of the gear pump is changed, its flow can be accurately known. Because the synchronous working speed of the upstream and downstream equipment and the gear pump can be determined, the pressure, temperature and other information collected at the inlet and outlet of the gear pump can be used to realize the online monitoring and feedback control of the whole extrusion process.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071

pre:How to properly maintain the bearings and gears of the melt pump?