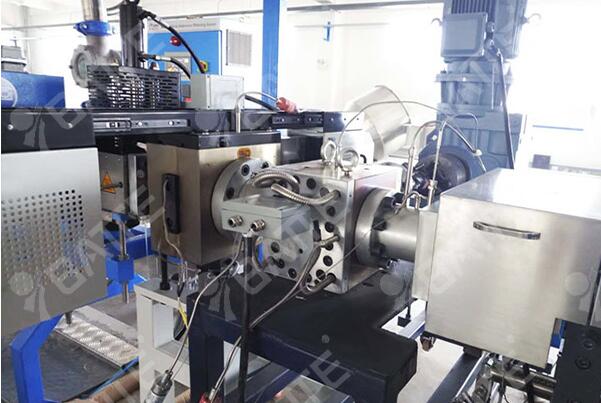

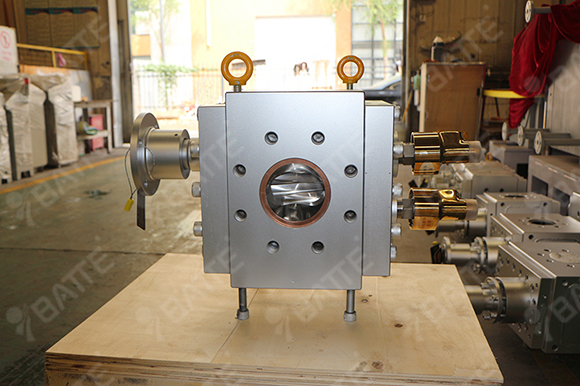

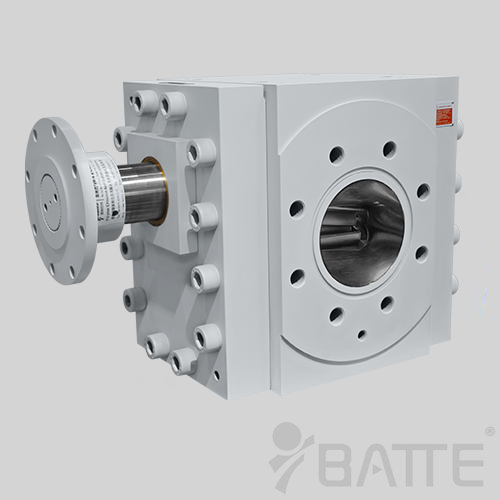

The extrusion melt pump for thermoplastic materials has a built-in cooling channel, which can control the temperature more quickly and efficiently; Equipped with optimized tooth shape design, the conveying is more stable with minimal fluctuations; Has a flow channel design without dead corners, without material residue; There are various wear-resistant configurations and sealing methods to choose from, suitable for high filling conditions, and suitable for both electric heating and thermal medium heating.

The function of extrusion thermoplastic melt pump

1. Significantly improve the stability of die head pressure and improve product quality.

2. It can achieve near linear output of flow and is easy to control.

3. Increase extrusion volume and increase production.

4. Reduce extruder load, save energy, and reduce costs.

Characteristics of plastic extrusion melt pump:

1. Minimal pressure and flow pulsation can achieve linear output of flow, suitable for precision extrusion systems.

2. Adopting different structures and material configurations for different working conditions can better meet the personalized needs of users.

3. It can be applied to high temperature (350 ℃), high pressure (40MPa), and high viscosity (40000 Pass) working conditions.

4. Precision structure, high precision, and long service life.

Since its establishment, Zhengzhou Batte Melt gear Pump has nearly 20 years of experience in the application of melt pumps in extrusion systems. It can provide a variety of melt pumps for extrusion systems such as various sheets, plates, pipes, films, wire drawing, underwater cutting, master batch extrusion granulation, rubber preforming, etc. It is widely used in various polymer polymer materials.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071

pre:The role of plastic sheet melt pump in the extrusion system

next: Application of Melt Pump in Chemical Fiber PET/r-PET/PA Industry