Melt pumps generate pressure more efficiently than screw extruders and provide more consistent pressure and output than screw extruders, which fill the gears from the suction side and rotate the gears to discharge the polymer from the other side. Melt pumps don't just discharge a constant volume of melt, they are more efficient than screws at generating extrusion pressure, and they can also be used as mixing devices.

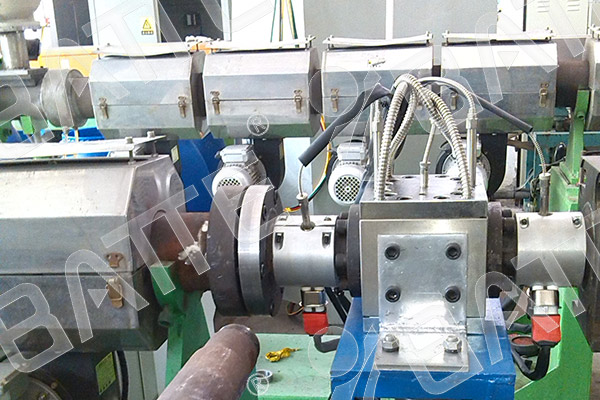

melt pump for extruder

By controlling the melt output, it eliminates many of the variables that affect the stability of extruder output. Melt pumps can compensate for problems such as poor or erratic temperature control, feed interruptions, variations in the polymer mixture, and fluctuations due to screw design. Because melt pumps solve many of the extruder's output stability problems, the operator is free to focus on the mold and downstream equipment.

thermoplastic melt pump manufactuer

The main purpose of the melt pump is to control the output to the mold. The melt pump consists of two gears, usually driven by a single motor. The extruder fills the gears from the suction side and the rotating gears discharge the polymer from the other side. A well-made gear will have an extraordinary profile, and the volume of plastic in each tooth will be extraordinary when that gear is enclosed in a tight-fitting housing. As the gears turn, they meter the exact amount of plastic on the discharge side. Zhengzhou Bart offers melt pumps in sizes ranging from 0.08CC to 20,000CC, as well as non-standard customized production.

melt pump manufacturer

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:Do you understand the spiral seal of the melt transfer pump?

next: Analysis and Solution of Leakage Causes of Spinning Metering Pump