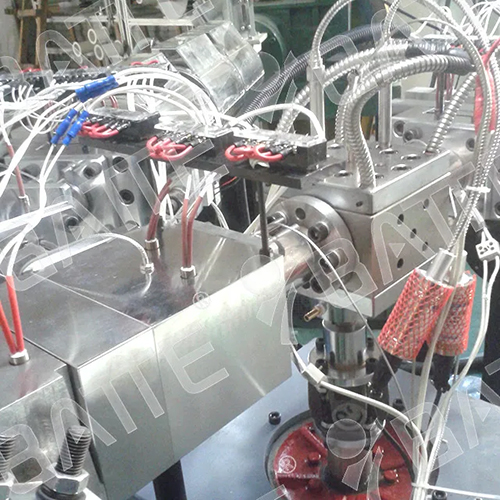

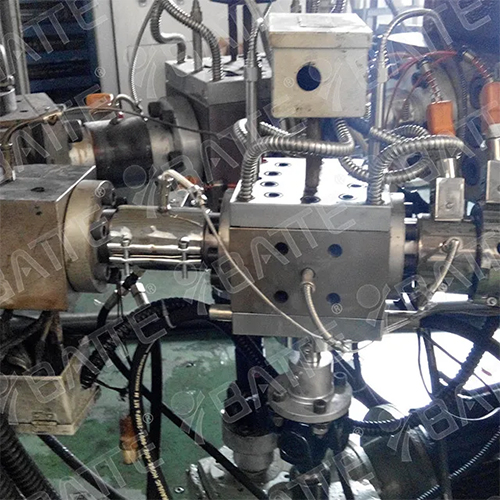

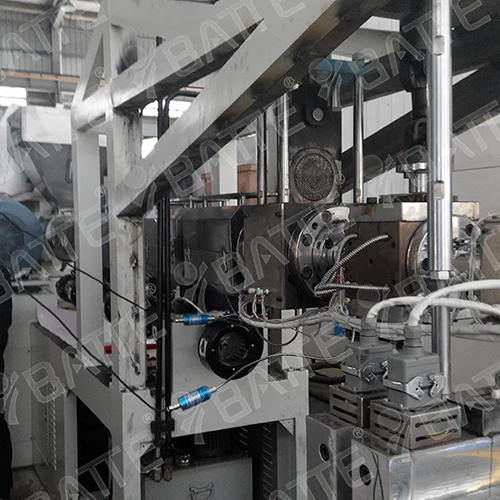

Zhengzhou BATTE is familiar with the extrusion process of all kinds of plastics and rubber materials, and has a lot of experience in the application of melt pumps for extrusion systems, providing a variety of melt gear pumps for extrusion systems of various sheets, plates, tubes, films, wire drawing, underwater pelletizing, masterbatch pelletizing, rubber preforms, etc., which are widely used for all kinds of polymer polymer materials. Melt gear pumps for extrusion systems, also known as melt metering pumps, are used in extrusion systems for various plastics, rubber, elastomers and other materials. They can be used in various extrusion industries, such as sheet, plate, pipe, film, granulation, wire drawing, cable, co-extrusion, mixing, precision extrusion and other industries.

The main role of melt pumps for extrusion system

1、Significantly improve the stability of the die head pressure, and improve product quality.

2, can realize the flow of nearly linear output, easy to control.

3、Increase the extrusion volume, improve the output.

4、Reduce the extruder load, save energy, reduce costs.

Extrusion system with the main characteristics of the melt pump

1, very small pressure flow pulsation, can realize the flow of linear output, suitable for precision extrusion system.

2, for different working conditions using different structures and materials configuration, to better meet the user's individual needs.

3、It can be applied to high temperature (350C), high pressure (40MPa), high viscosity (40.000Pass) working conditions.

4、Precise structure, high precision, long life.

Zhengzhou BATTE provides high wear-resistant and corrosion-resistant melt pumps, which are applied in high filling and corrosive working conditions.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071