Melt gear pump is a kind of precision instrument with high accuracy and stability, which is widely used in chemical fiber, petrochemical, pharmaceutical, food and other fields. According to different use occasions and process requirements, melt gear pumps have a variety of types to choose from. This article will introduce the three types of melt gear pumps and their characteristics in detail.

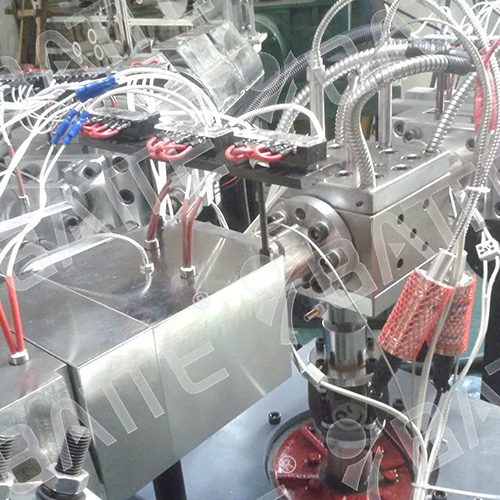

Straight tooth melt gear pump

Straight tooth melt gear pump is the most basic type, its structure is simple, easy to manufacture, easy maintenance, suitable for low viscosity fluid media. Due to the straight tooth gear pump pump cavity is small, the flow uniformity is relatively poor, so it is easy to clog when used in high viscosity fluid media. In addition, straight gear pumps are noisy and vibration is more obvious.

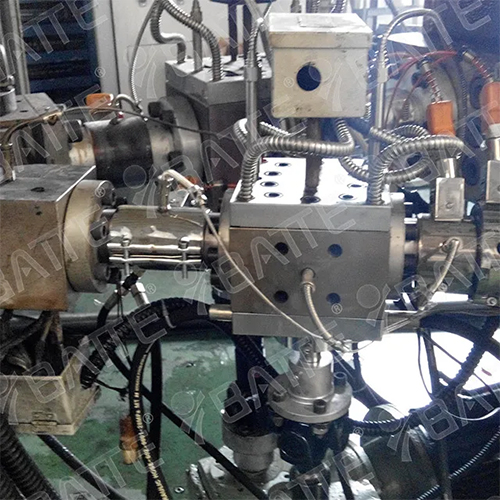

helical tooth melt gear pump

Helical tooth melt gear pump has the following advantages compared with straight tooth melt gear pump:

1. Better flow uniformity: the pump chamber of helical tooth gear pump is larger, the flow path is gentle, not easy to block, suitable for high viscosity fluid medium.

2. Lower noise: helical gear pump adopts helical gear design, smooth running, better gear meshing, so the noise is lower.

3. Can withstand higher pressure: the pump body of helical gear pump adopts integral design, higher strength, can withstand higher working pressure.

Helical tooth melt gear pump

Spiral tooth melt gear pump is a special melt gear pump, its flow uniformity is better, can be applied to high viscosity, high solid content of the fluid medium. Its structural characteristics are as follows:

1. Adopting spiral teeth design: the design of spiral teeth makes the flow path in the pump cavity more gentle, reduces the friction and resistance of the fluid, and improves the flow uniformity.

2. Pump body adopts integral design: The pump body of spiral tooth melt gear pump adopts integral design, which has higher strength and can withstand higher working pressure. At the same time, the integral design also facilitates maintenance and replacement of parts.

3. High temperature resistance: spiral tooth melt gear pumps are generally made of high temperature resistant materials, which can withstand higher working temperatures and are suitable for the transportation of high temperature melts.

4. Low shear force: the design of helical teeth makes the fluid flow more smoothly in the flow channel, reduces the shear force of the fluid, and is suitable for conveying polymer materials and high viscosity fluids.

In summary, straight tooth melt gear pumps, helical tooth melt gear pumps and spiral tooth melt gear pumps have their own characteristics and scope of use. When choosing melt gear pumps, it is necessary to choose according to the actual use requirements and process conditions. For example, for low viscosity fluid media, you can choose straight tooth melt gear pumps; for high viscosity fluid media or need to withstand higher working pressure, you can choose helical tooth melt gear pumps; for the need to transport polymer materials and high viscosity fluid, you can choose spiral tooth melt gear pumps.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071