Polymer gear pump is an important component of hydraulic system, its function is to transport hydraulic oil from low pressure state to high pressure state, providing power for the entire hydraulic system. The structure and working principle of gear pumps directly affect the performance and stability of hydraulic systems. This article will focus on the characteristics, structure, working principle, and application of pipeline gear pumps.

The characteristics of pipeline gear pumps

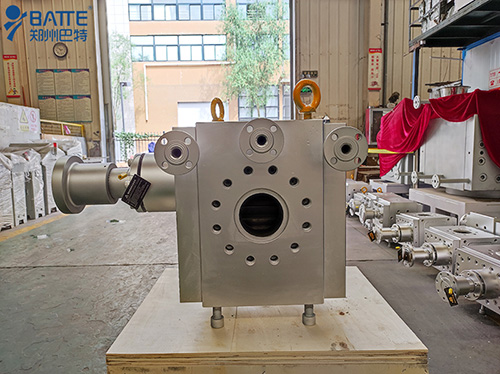

Pipeline gear pump is a common hydraulic component with the characteristics of simple structure, small volume, light weight, low cost, reliable operation, and convenient maintenance. It mainly consists of gears, shafts, pump bodies, pump covers, etc. Among them, gears are the core components, and their shape and accuracy directly affect the performance of gear pumps.

The structure of pipeline gear pump

The structure of a pipeline gear pump mainly consists of the following parts:

1. Gear: It is the core component of a gear pump, and its shape and accuracy directly affect the performance of the gear pump.

2. Shaft: It is the transmission shaft of a gear, which connects the gear to the prime mover and allows the gear to rotate on the shaft.

3. Pump body: It is one of the key components of a gear pump, which has meshing holes that match the gears and inlet and outlet ports connected to pipelines.

4. Pump cover: It is used to fix and protect the pump body, and can also serve as a bearing cover to support and protect the shaft.

Working principle of pipeline gear pump

The working principle of a pipeline gear pump is that when the electric motor drives the gear to rotate through the shaft, the gear meshes with the pump body, delivering hydraulic oil from a low-pressure state to a high-pressure state. At the inlet and outlet of the pump body, the pressure of the oil will change, thereby achieving pressure transmission in the hydraulic system.

The application of pipeline gear pump

Pipeline gear pumps have a wide range of applications in hydraulic systems, such as machine tools, forging machinery, injection molding machines, hydraulic stations, etc. It can serve as a power source for hydraulic systems, providing sufficient power to the executing components, and can also be used as a hydraulic control valve to achieve pressure and flow control in hydraulic systems.

In summary, as a common hydraulic component, pipeline gear pumps have the characteristics of simple structure, small volume, light weight, low cost, reliable operation, and convenient maintenance. It is widely used in various hydraulic systems to provide power for the actuating components, while also achieving pressure control and flow control in hydraulic systems. In the future development, with the continuous progress of technology and the increasing demand for applications, the performance and stability of pipeline gear pumps will also be further improved.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:Advantages and applications of high temperature melt pumps