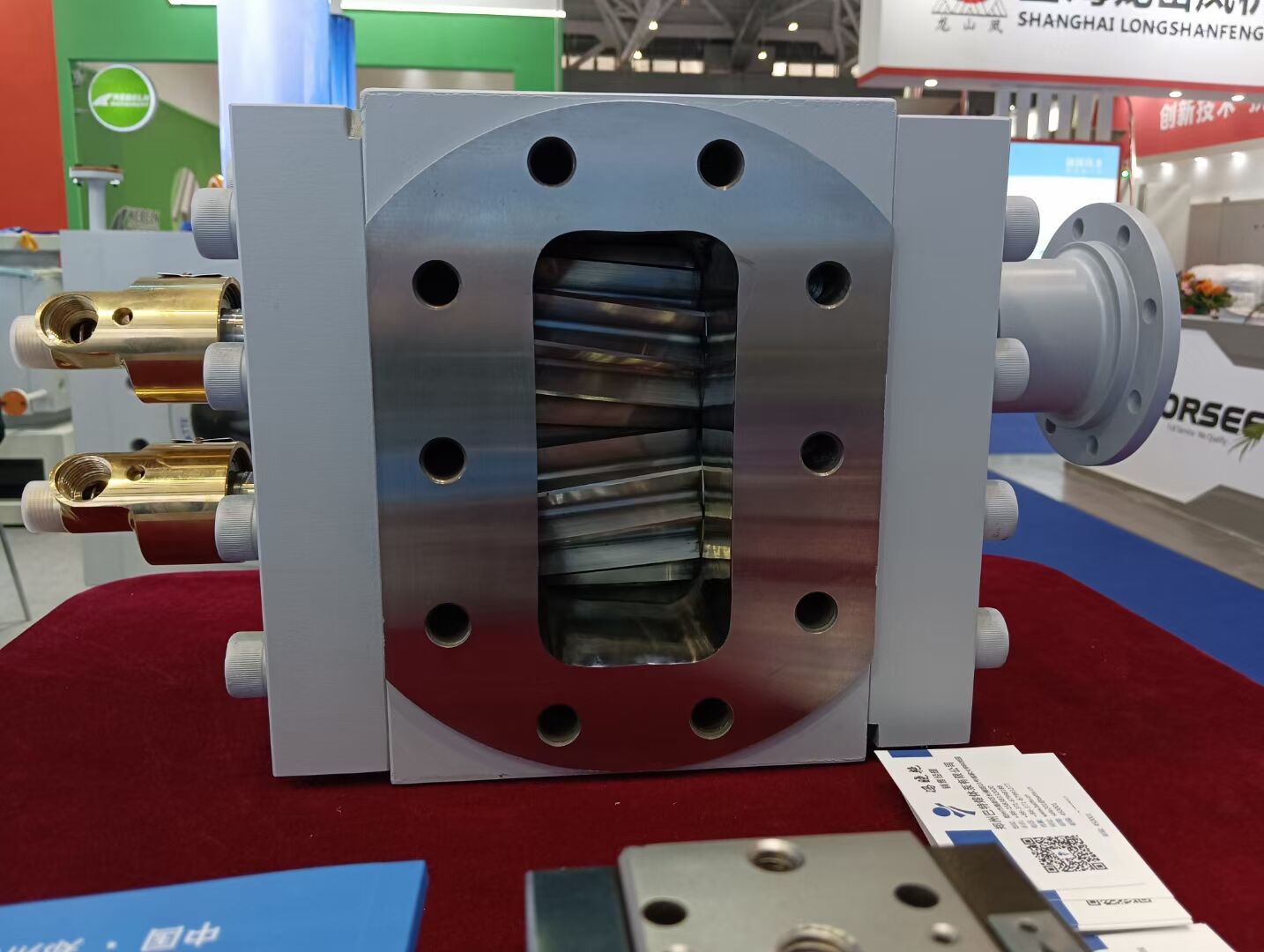

High viscosity melt gear pump is a special type of pump mainly used for conveying high viscosity fluids. Compared with conventional pumps, high viscosity melt gear pumps have differences in design, structure, and materials, which can better adapt to the transportation requirements of high viscosity fluids.

The main characteristics of high viscosity melt gear pumps include:

1. Strong adaptability: High viscosity melt gear pumps can adapt to the transportation of various high viscosity fluids, such as molten materials in industries such as plastics, rubber, and food.

2. Wide viscosity range: High viscosity melt gear pumps can transport fluids with a very wide viscosity range, adapting from low viscosity to high viscosity.

3. High conveying efficiency: Due to the use of gear transmission in high viscosity melt gear pumps, efficient conveying can be achieved, reducing energy waste.

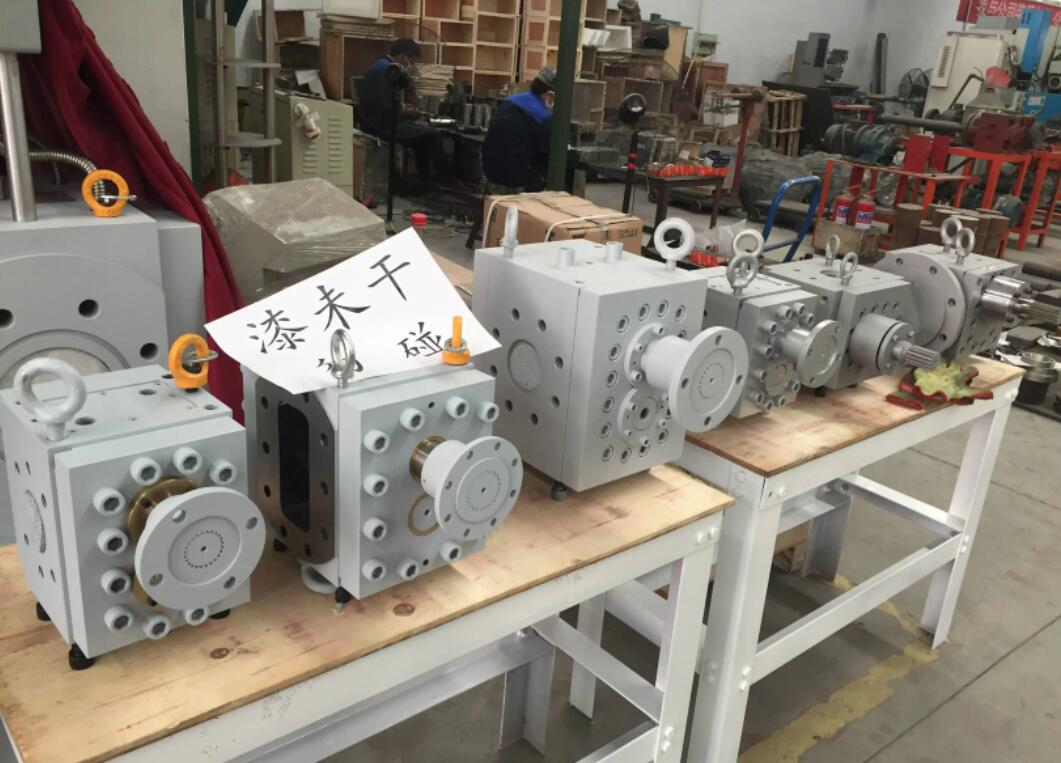

4. High reliability: The high viscosity melt gear pump adopts high-quality materials and precision machining technology, which has high reliability and durability and can ensure long-term stable operation.

5. Easy maintenance: The high viscosity melt gear pump has a simple structure, is easy to disassemble and repair, and daily maintenance is also relatively convenient.

In order to achieve efficient, stable, and safe transportation of high viscosity fluids, the design, manufacturing, and use of high viscosity melt gear pumps need to pay attention to the following aspects:

1. Design aspect: In the design, it is necessary to fully consider the characteristics, temperature, pressure and other parameters of the fluid, select appropriate materials and structures, and improve the adaptability and durability of the pump. At the same time, attention should be paid to improving the transmission efficiency of the pump and reducing energy loss.

2. In terms of manufacturing: it is necessary to ensure the machining accuracy and assembly quality of the pump, and ensure that the machining and assembly accuracy of key components such as gears and bearings meet the requirements, in order to improve the operational stability and reliability of the pump.

3. In terms of use: During use, it is necessary to strictly follow the operating procedures to avoid overloading and illegal operations, in order to ensure the safety and service life of the pump. At the same time, it is necessary to strengthen daily maintenance and upkeep, regularly inspect and replace vulnerable parts, and maintain the pump in good working condition.

4. Maintenance: The pump should be regularly disassembled, inspected, and repaired, and wear and tear parts and vulnerable parts should be replaced in a timely manner to ensure the normal operation of the pump. At the same time, attention should be paid to training and technical support for maintenance personnel to improve maintenance quality and efficiency.

In summary, high viscosity melt gear pumps, as a special type of pump, have broad application prospects and market demand. In order to achieve efficient, stable, and safe transportation of high viscosity fluids, it is necessary to start from multiple aspects such as design, manufacturing, use, and maintenance to improve the performance and quality of the pump. At the same time, we need to strengthen technological research and innovation, constantly innovate and meet the needs of different fields and industries, and promote the sustainable development of the high viscosity melt gear pump industry.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:How much melt can the 100CC melt pump output per revolution?

next: Analysis of Fluid Dynamic Pressure Thrust Lubrication Principle by Bart Melt Pump Manufacturer