Zhengzhou Batte has domestic melt pump processing equipment and processes, ensuring the provision of the new generation of melt pump equipment with advantages such as high precision and no pulsation. Zhengzhou melt pump manufacturer will analyze in detail the lubrication principle of fluid dynamic pressure thrust on the melt pump below.

The principle of fluid dynamic pressure lubrication is generally applied in mechanical seals and thrust bearings, which is used to counteract the additional axial force on the gear shaft of the melt pump. In fact, it also utilizes the lubrication principle, but the application scenarios are different. In mechanical seals, the sealing medium is generally a low viscosity liquid, so the speed is generally high and the depth of the groove is small. When sealing gas, the depth of the groove can reach micrometers. The gear structure design of the melt pump plays a crucial role in the operation of the melt pump. If a regular involute helical gear with a pressure angle of 20 degrees is used, the helical gear can increase the overlap of gear meshing, and during meshing, the material can be continuously and smoothly squeezed, reducing pressure fluctuations in the melt pump. In addition, helical gears also have a certain self-cleaning effect, which can avoid the deposition and decomposition of materials. Although it has great advantages in reducing pressure fluctuations and self-cleaning, this form of gear will generate axial force during operation, affecting the service life of bearings and intensifying the shear degree of the melt in the tooth side clearance, reducing the volume of the melt pump.

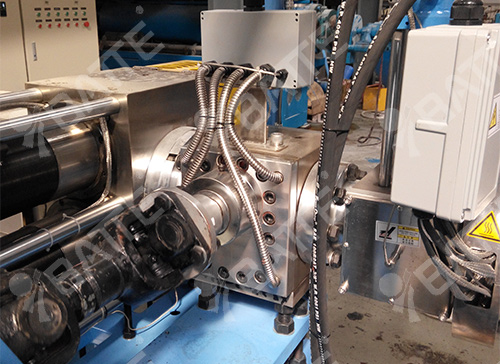

Zhengzhou Batte Melt Pump Co., Ltd. is a professional thermoplastic melt pump manufacturer in Henan, China, providing new generation melt pump equipment including ZB-H high-temperature and high-pressure melt pump, ZB-C reinforced melt pump, extruder specific melt pump, etc.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:Characteristics and precautions of high viscosity melt gear pumps