We are here to help.Easy ways to get the answers you need.

Pipe production is divided into PE solid wall pipe, corrugated pipe, drip irrigation belt, PPR pipe, PERT floor heating pipe, steel wire reinforced pipe, steel belt winding pipe, carbon pipe, gas pipe, communication pipe, polyurethane foam insulation pipe, etc.

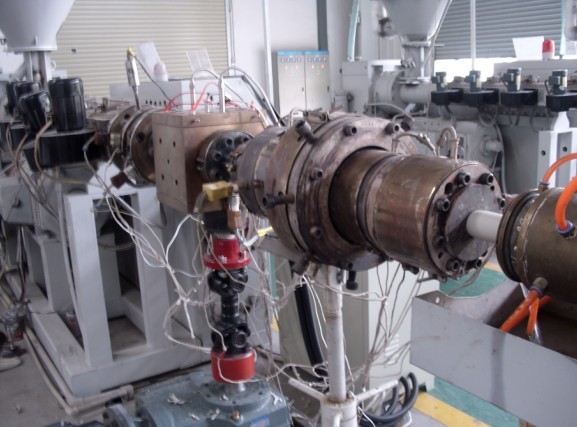

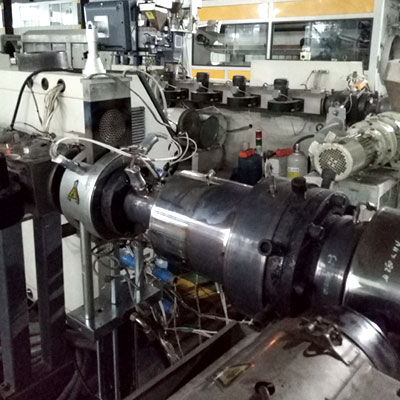

The melt pump for pipe adopts high precision gear gap, which can effectively reduce the pressure of the barrel during the extrusion process, reduce the friction between the screw and the barrel, reduce the load of the thrust bearing of the gear box, and can effectively solve the problem of exhausting and bubbling material from the extruder. The pump adopts filling seal and mechanical screw seal to effectively prevent the leakage of rubber. It has the characteristics of high temperature resistance, high pressure, high wear resistance and corrosion resistance, etc. It strengthens the requirements of high torque and low shear of the pump body, and the pump body has the characteristics of high finish, and the self-lubrication system and import and export flow channels are optimized, and the linear flow channel design is adopted to effectively reduce the residence time of the material in the pump, so that the material can achieve the best plasticizing effect and realize stable and balanced extrusion. It is more suitable for the extrusion of PC, PMMA and other transparent products and PVC heat-sensitive materials.

1. It can achieve stable extrusion, improve the dimensional accuracy of extruded products and reduce the scrap rate. During the extrusion process, it is difficult to avoid uneven material addition, fluctuation of barrel and head temperature, and pulsation of screw speed. The use of melt gear pump can eliminate the charging error of the charging system, which can greatly reduce the fluctuation of upstream process transmission, and quickly enter into a stable working condition, improve the dimensional accuracy of extruded products and reduce the scrap rate.

2. Increase output, reduce energy consumption, realize low temperature extrusion and extend the life of the machine. Since the extruder is installed with polymer melt pump, the decompression function of the extruder is transferred to the gear pump to complete, the extruder can work under low pressure and low temperature, the leakage flow is greatly reduced and the output is increased. Gear pump is easier than the extruder to effectively establish the head pressure, and can reduce the back pressure of the extruder, so that the axial force on the screw is reduced, extending the service life.

3. With linear extrusion characteristics, it is easy to coordinate the work of upstream and downstream equipment. As the gear pump leakage flow is less, the pump conveying capacity is basically linear with the speed, and the flow rate can be known exactly after the gear pump speed is changed. As the working speed of the upstream and downstream equipment synchronized with the gear pump can be determined, the whole extrusion process can be monitored online and controlled with feedback by using the information data of pressure and temperature collected at the entrance and exit of the gear pump.

PE solid wall pipe (water supply pipe, drainage pipe) production screen changer is generally installed between the extruder barrel flange and die flange, bolts through the flange fixed in the screen changer screw hole. PE pipe extruder is now divided into high-speed machine and ordinary machine, general ordinary machine according to the conventional selection principle configuration screen changer, high-speed machine is based on the original configuration to increase a specification. Net, high cost performance, easy and fast to change the net, no stop to change the net (the diameter of small diameter coils below 25mm to stop or slow down to change the net), no leakage of material, the majority of customers have been widely recognized. Small diameter pipe or manufacturers with higher requirements for automation can use Batte mesh belt type automatic screen changer, no manual operation, fully automatic production, continuous production, no material leakage, is to adapt to the current market upgrade screen changer products, the price is slightly higher than the plate type screen changer, but the labor cost is reduced.

Double-wall bellows production line is also divided into high-speed machine and ordinary machine, general ordinary machine according to the conventional selection principle configuration screen changer, high-speed machine is configured on the original basis to increase a specification. Double-wall corrugated pipe selection for Batte plate type double-station screen changer, the inner and outer wall at the same time installed screen changer, the use of one drag two accumulator hydraulic station, cost-effective, convenient and quick to change the screen, no downtime to change the screen (inner wall, outer wall, successively change the screen), no leakage of material, the majority of customers have been widely recognized. Individual manufacturers only install the screen changer on the outer wall extruder, and the main machine should be moved backward a certain distance when installing the screen changer.

PERT floor heating pipe production screen changer is generally installed between the extruder barrel flange and the die flange using a double column double station screen changer. Because of the good fluidity of PER melt, thin pipe wall, and certain requirements for the production of connectivity, so the double-column duplex screen changer is very suitable for the choice, no stopping to change the screen (set with priming and exhaust device), no leakage, widely used in production, and has been verified by the production and customer recognition.

Steel wire reinforced pipe production installation screen changer can be installed between the barrel flange and die flange of the main machine and auxiliary machine of the extruder according to the process requirements of production, and the bolt is fixed through the flange on the screw hole of the screen changer, or only on the auxiliary machine. For manufacturers with higher automation requirements, Batte mesh belt type automatic screen changer can be used, no manual operation, fully automatic production, continuous production, no material leakage, is to adapt to the current market upgrade screen changer products, the price is slightly higher than the plate type screen changer, but the labor cost is reduced.

Batte specializes in the research and development and production of melt filter/screen changer, melt metering gear pump and its accessories for nearly 20 years, understanding the characteristics of most thermoplastic materials, and has accumulated rich experience in the use of equipment, according to user needs, PP-R pipe, PE solid wall pipe, corrugated pipe, drip irrigation belt, PPR pipe, PERT floor heating pipe, steel wire reinforced pipe, steel belt winding pipe, carbon pipe, gas pipe We can provide better solutions for PP-R pipe, PE solid wall pipe, corrugated pipe, drip irrigation belt, PPR pipe, PERT floor heating pipe, steel wire reinforced pipe, steel band winding pipe, carbon pipe, gas pipe, communication pipe, polyurethane foam insulation pipe characteristics, production principle, common materials, process characteristics, heating temperature, processing pressure, output, etc.