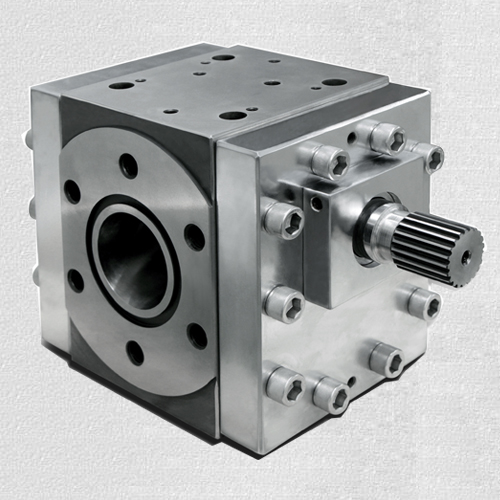

The high viscosity melt pump is a rotary positive displacement pump of internal gear pump. The liquid flow is generated by two gears that engage each other. The active and driven gears are embedded in the external transmission gears and separated by a crescent-shaped separator. When the transmission gear rotates, the material liquid is sucked into the space composed of two transmission gears and crescent-shaped baffles. When the transmission gear teeth engage, the liquid force is excluded from the pump. Therefore, the fluidity of liquid is stable, the volume is large and the structure is compact.

High viscosity gear melt pump has a jacket pump dedicated to leaching design: asphalt pump with temperature control, which can quickly melt the solid leaching in the pump before starting. In the support frame, there are jacket candidates in the bearing end cover and rolling bearing area, which can prevent leaching from drying and solidifying in the pump.

Centrifugal melt pump can be widely used in power engineering, metallurgical industry, coal, decorative building materials and other industries with liquid particulate matter slurry conveyor. Such as ash removal in power plant, slurry conveyor in metallurgical industrial concentrator, slurry conveyor in coal preparation plant and dense medium conveyor, etc. When the centrifugal pump works, the pump needs to be put on the land, the hygroscopic pipe into the water, and the irrigation pump needs to start.