The melt pump in XPS foam sheet extrusion industry

The melt pump in XPS foam sheet extrusion industry:

A, XPS foam sheet size :( width mm * Thickness mm) 60 * 2 60 * 2.5 60 * 3 60 * 3.5 60 * 5 60 * 10

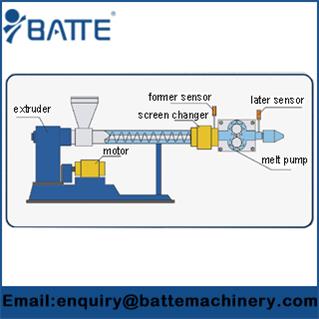

The main production equipment: two-stage extruder (Φ135 and Φ150 screw)

Φ135 supporting equipment: screen changer temperature zone 8, respectively 172 ° C 156 ° C 160 ° C 160 ° C 144 ° C 218 ° C 240 ° C

Φ150 supporting equipment: melt pump, mixing, switches, mold temperature machine, sheet metal molds.

Temperature zone is seven, respectively: 202 ° C 162 ° C 158 ° C 146 ° C 110 ° C 66 ° C 75 ° C

Φ135 Screw Parameters: Motor Power 75KW, frequency 105, speed 30.4 r / min

Φ150 Screw Parameters: Motor Power 55KW, frequency 79, speed 39 rev / min

The melt pump parameters:

Model MP-M-315CC inverter motor power 18.5KW PID

Control system:

Gear pump for extrusion temperature 125 ° C

outlet temperature: 116 ° C.

Speed: 12rpm

current 27A

the kneading temperature of 125 ° C

mold temperature of 150 ° C die

temperature: 70 ° C

foaming parameters: flon into the pressure 25MPa.

Conclusion: XPS foam production line was added after the melt pump advantages:

1. Reduce the proportion.

2. The temperature inside and outside the XPS sheet pressure drop, uniform temperature, can solve the problem of bending sheet.

3. You can increase the pressure in the mold required.

4. Can sectional dimension accuracy of the temperature XPS sheet.

Relative Articles:

◆Fluoropolymer gear pump

◆Melt pump extrusion manufacturing

◆How to troubleshoot profile extrusion

◆Internal Gear Pump

pre:How is extrusion gear pump used

next: Information about Batte melt pumps gear pumps metering pumps