Before installing the melt gear pump, measure and adjust the concentricity between the pump seat and the motor drive shaft to ensure that the melt pump shaft rotates in the direction indicated when ordering, otherwise it may cause input shaft fracture and pump body damage.

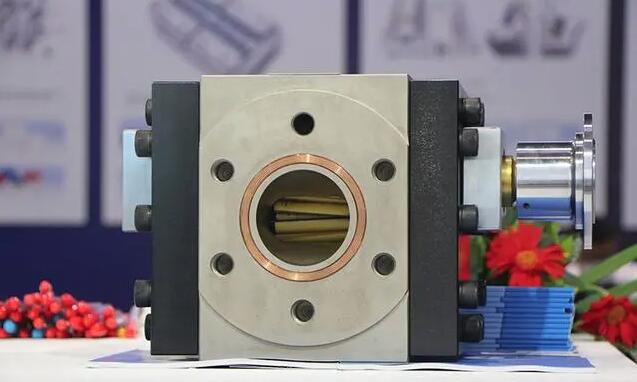

sheet extrusion pump

The base of the sheet extrusion pump installation should be flat and have sufficient strength and rigidity; Under the condition of evenly tightening the bolts, it should be ensured that the input shaft of the pump can rotate uniformly without jamming.

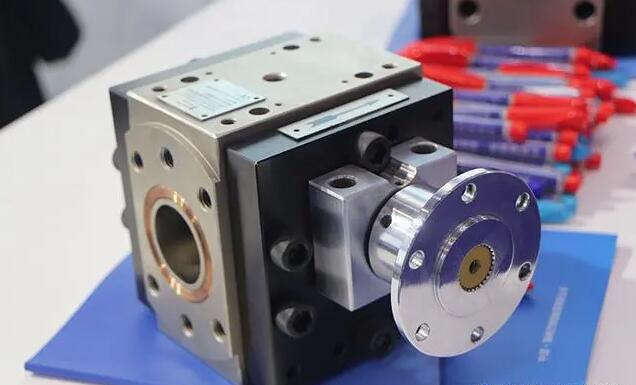

melt gear pump

The installation error of the universal coupling should not exceed its allowable deviation value, and the deviation value should be less than 3 degrees. To avoid causing additional force and shortening the lifespan of the shaft. Tighten the screws evenly during installation.

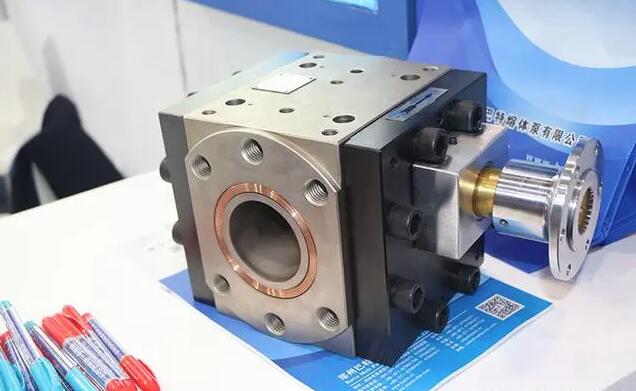

thermoplastic melt pump manufactuer

Before running the extrusion melt pump, it should be evenly heated and the temperature should not exceed 120 ℃ per hour; Do not forcefully start the melt pump before the pump reaches operating temperature. (Working temperature refers to the melting temperature of the materials used under on-site process conditions)thermoplastic melt pump manufactuer

polymer melt pump

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:Small specification high-pressure reactor melt discharge pump