The development of the melt pump market is based on demand. Due to the increasing demand for rubber and plastic in the market. In the extrusion production line, the high-temperature melt pump is mainly used for boosting and stabilizing pressure. Compared to other types of melt equipment or boosting equipment, the price of high-temperature melt pumps is not high. The sales prices of different types of melt pumps are completely different, so what are the important factors that determine the price of high-temperature melt pumps?

1. The magnitude of energy consumption

The primary factor determining the price of high-temperature melt pumps is the magnitude of energy consumption. Relatively speaking, prices are higher for those with lower energy consumption, while prices are lower for those with higher energy consumption. The energy consumption of similar equipment produced by different manufacturers varies. Choosing equipment with low consumption is a wise choice, even if the price is high, it is still a good choice, at least to ensure unnecessary energy consumption.

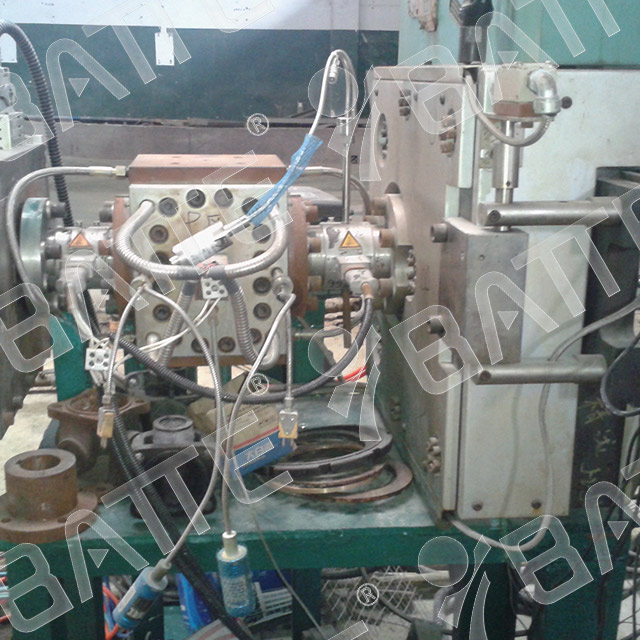

2. Yield level

The level of production is the key to determining efficiency, and the price of melt pumps that can bring high efficiency is often relatively high. And the benefits brought by lower output melt pumps are also relatively low, which will have a certain impact on their market sales prices. The higher the output, the higher the price of the equipment, and there is a gap in the sales price of equipment with different outputs in the market.

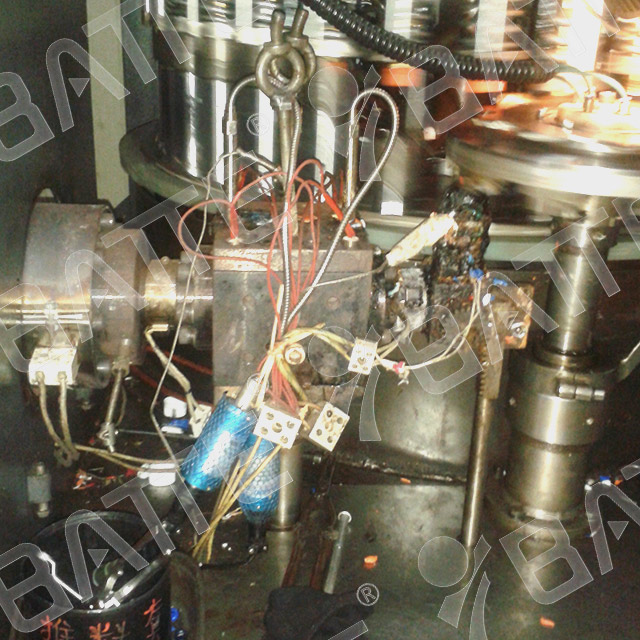

3. Volume size

The volume size is the key to determining the amount of feed and production. Relatively speaking, while ensuring a larger feed volume, its output and work efficiency will also be greatly improved. Therefore, larger volumes have slightly higher prices, while smaller volumes have lower prices. Moreover, the cost varies depending on the size of the volume, and the higher the cost, the higher the natural price.

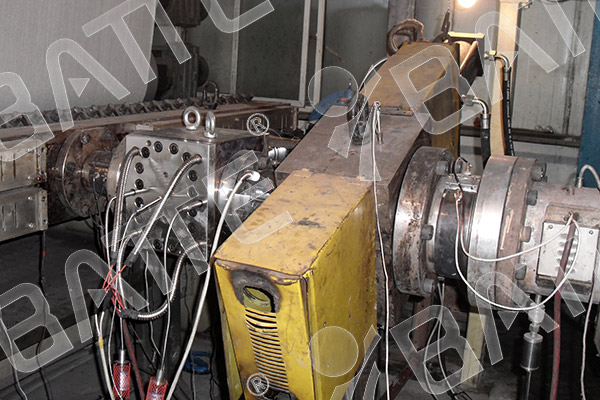

4. Convenience of maintenance

Many times when choosing a melt gear pump, people overlook the convenience of maintaining the melt pump. Generally, professional manufacturers pay attention to the design of the structure when producing plastic extrusion melt pumps to ensure convenient maintenance. The price of high maintenance convenience will also be higher.

These are the price factors that determine the high-temperature polymer melt pump. These comprehensive factors determine the price and also determine the abnormal development trend of such melt pumps. At present, there are many manufacturers producing this type of equipment in the market. When choosing, it is important to pay attention to analyzing the rationality of the price based on the above details. Choosing equipment with high cost-effectiveness is the best choice, which is the key to reducing unnecessary expenses and ensuring low maintenance costs. It is also the key to determining the level of revenue brought by the equipment.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071