Heat treatment of gears for melt gear pumps, there are several heat treatment heating methods?

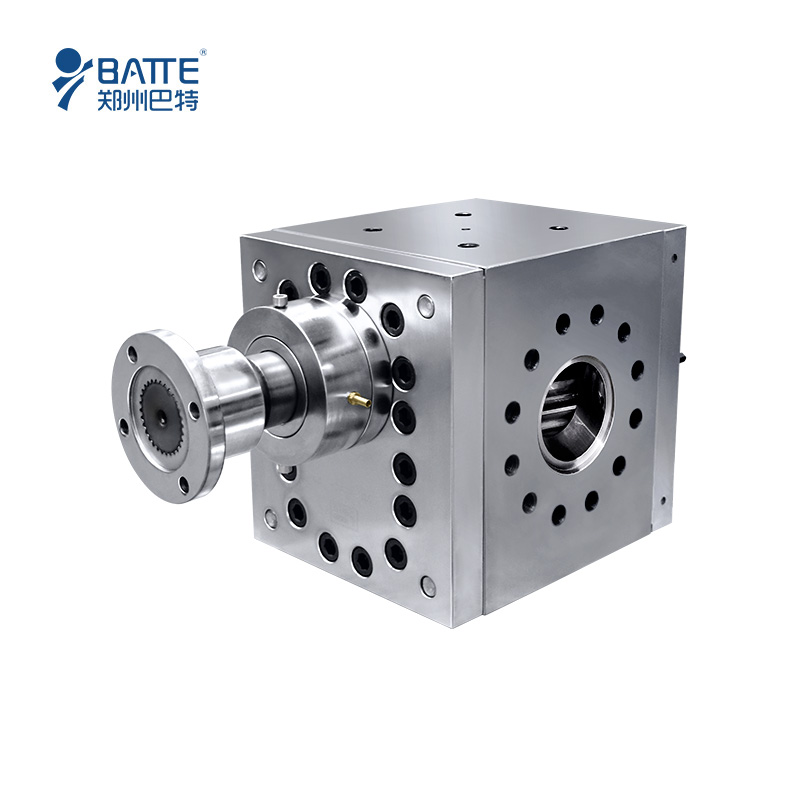

1, surface hardening treatment, such as nitriding. Torque transfer characteristics, not easy to break under high loads, but the metal surface and the internal hardness difference is too large, easy to cause hard metal on the soft metal layer of extrusion damage.

2, quenching treatment. Have very good anti-wear properties, and due to the destruction of the surface layer will not make the whole gear rapid failure. Its disadvantage is that the harder the gear, the more likely to be damaged, sensitive to torque and vibration.

3、Surface hardening after quenching treatment. This treatment will not make the surface and internal hardness difference is too large, with strong resistance to surface damage, excellent transmission torque and other characteristics.

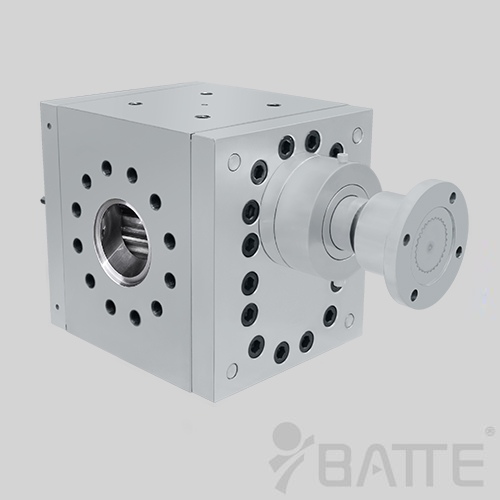

thermoplastic melt pump manufactuer

Among them, the heat treatment of gears is tempered nitriding (oxide layer thickness is more than 0.3~0.5mm), and the hardness is 300HBS.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:What are the important factors determining the price of high-temperature melt pumps