In order to effectively extend the service life of the melt gear pump, it is necessary to clean it regularly after use. It is necessary to inject clean water into the pump, connect the power supply according to the usual steps, wait for the heating and discharge, and then proceed with the shutdown procedure. And what are the benefits of doing so? Next, the melt pump manufacturer will explain to everyone one by one.

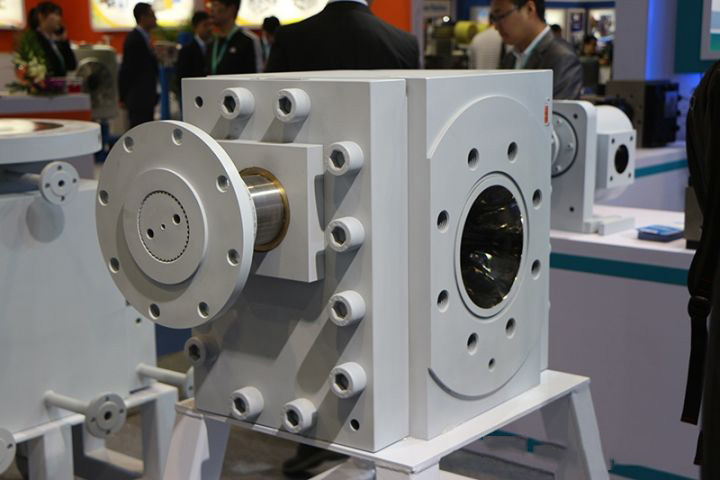

polymer melt pump in extruder

1. clean the internal impurities, ensure internal cleanliness, improve equipment operation efficiency, and reduce wear.

2. Avoid overlapping the materials that were not used up last time with the materials processed next time, and extrude mixed materials.

3. Some materials have a high melting point, while others have a low melting point. Mixing and heating may cause deformation and damage to the extruded material, thereby reducing the yield.

4: Regularly maintain the melt pump to greatly improve its lifespan.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:Melt pump gear heat treatment heating mode

next: Combining plastic melt pump and extruder to improve efficiency