Melt gear metering pump for extruder is a kind of high-precision gear pump, usually made of stainless steel or high-strength wear-resistant materials, which is used for conveying high-temperature and high-pressure melt materials. Its structure is compact, simple, reliable and has a long service life. Melt gear metering pumps for extruders are widely used in plastics, chemical fiber and other fields.

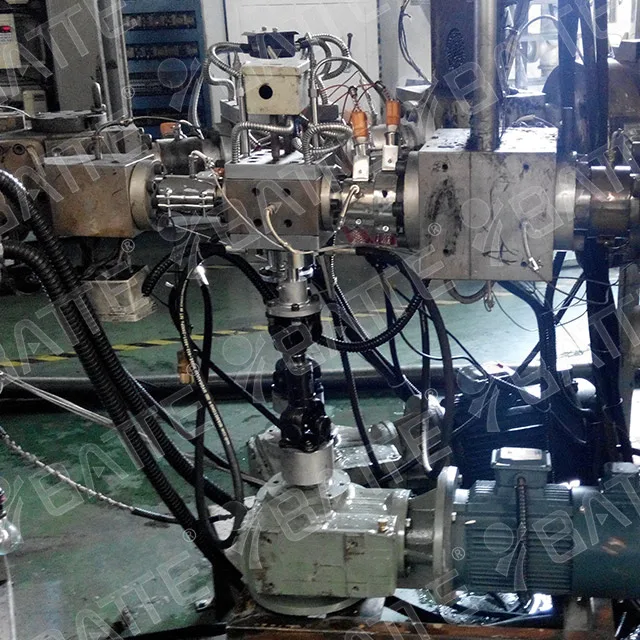

melt gear metering pump for extruder

Working principle of melt gear metering pump

The working principle of melt gear metering pumps is based on the rotation of gears to transport the melt material from the feed end to the discharge end. During the meshing process of the gears, the melt material is sucked between the teeth and pushed out with the rotation of the gears to realize quantitative conveying. The flow rate and pressure of the melt gear metering pump can be controlled by adjusting the speed and clearance of the gears.

polymer melt pump

Features of melt gear metering pump

1. High-precision flow control: Melt gear metering pumps can realize high-precision flow control, effectively guaranteeing the quality and stability of extruded products.

2. High-temperature and high-pressure resistance: Melt gear metering pumps are able to withstand high temperature and high pressure of the melt material, which makes them widely used in the field of plastics, chemical fiber and other polymer processing.

3. Simple and compact structure: the structure of the melt gear metering pump is simple and compact, easy to maintain, and has a long service life.

4. Adjustability: The flow rate and pressure of the melt gear metering pump can be controlled by adjusting the speed and clearance of the gears to meet the needs of different process conditions.

5. Good abrasion resistance: Melt gear metering pumps are usually made of stainless steel or high-strength abrasion-resistant materials, with good abrasion resistance, and can adapt to long-time continuous work.

melt pump for plastic extrusion

Melt gear metering pump maintenance

In order to ensure the normal operation and service life of the melt gear metering pump, regular maintenance is required. Mainly includes the following aspects:

1. Cleaning: Regularly clean the residues and impurities on the surface and internal channels of the melt gear metering pump to keep the equipment clean.

2. Inspection: regularly check whether the fasteners and seals of the equipment are intact and undamaged, and deal with any abnormalities in time.

3. lubrication: carry out regular lubrication maintenance according to the instructions of the equipment to ensure that the equipment is well lubricated.

4. Adjustment: Regularly adjust the parameters of the equipment to ensure that the flow and pressure of the equipment are controlled within the appropriate range.

5. maintenance: regular inspection and maintenance of equipment, timely detection and treatment of equipment failures and problems.

thermoplastic melt pump manufactuer

In short, the melt gear metering pump for extruder is a high-precision, high-temperature and high-pressure resistant, simple, compact and adjustable gear pump. It is widely used in plastics, chemical fiber and other fields. In order to ensure its normal operation and service life, regular maintenance is required.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:plastic scrap melt pump suppliers

next: Thermoplastic material melt gear pump role, characteristics, structure