Thermoplastic melt pump can significantly improve the stability of the die head pressure, improve product quality; can realize the flow of near-linear output, easy to control; increase the extrusion volume, improve production; reduce the load of the extruder, save energy and reduce costs.

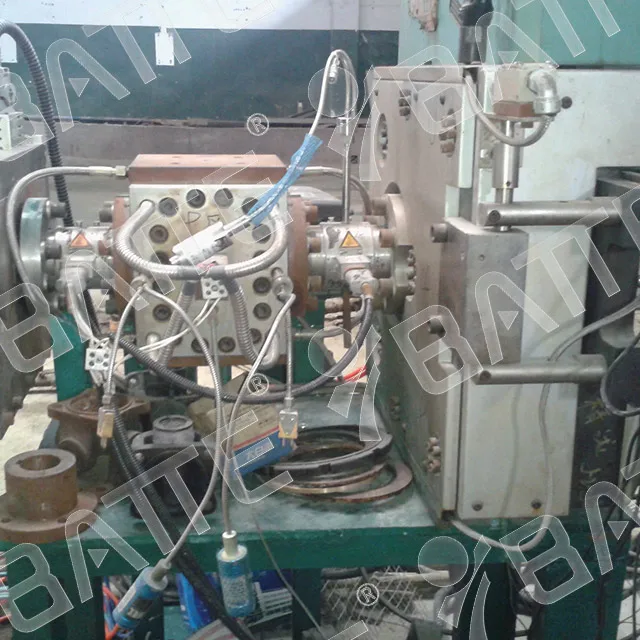

thermoplastic melt pump manufactuer

Thermoplastic extrusion pump have very small pressure and flow pulsation, and can realize the linear output of flow rate, which is suitable for precision extrusion system; different structures and material configurations are adopted for different working conditions to better meet the individual needs of users; it can be applied to high temperature (350℃), high pressure (40MPa), high viscosity (40,000Pass) working conditions; it has precise structure, high accuracy and long service life. High precision and long life.

Melt gear pumps for thermoplastic materials have built-in cooling channels, which can control the temperature more accurately and quickly; they have optimized tooth design, which makes the conveying more stable, with minimal fluctuation; they have dead-end channel design, with no material residue; they have a variety of wear-resistant configurations and sealing methods to choose from, and they are suitable for high-filling conditions, and are suitable for both electric heating and thermal media heating. thermoplastic melt pump manufactuer

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:Do you know the melt gear metering pump for extruder?

next: Melt Pumps for Sheet Film Extrusion Application Areas, Composition and Materials