The daily maintenance work of plastic sheet melt pump seal is less. The main inspection items are: leakage of shaft end of melt pump, pressure of sealing chamber, liquid level of sealing liquid, leakage of sealing system, etc. It is particularly important to check the liquid level of sealing liquid in plastic melt pump when it is open or shut down, because the pressure fluctuation is relatively large during the process of opening and shutting down. If there is no sealing liquid, the gas can easily leak into the system through the shaft end of the melt pump, thus causing the failure of the follow-up equipment of the melt pump, such as the pellet cutter.

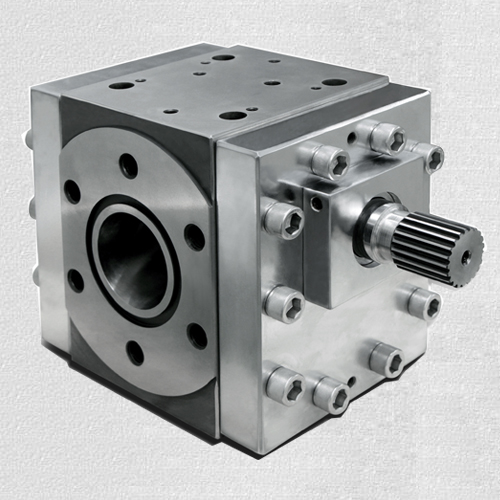

If the leakage occurs at the shaft end of the plastic sheet melt pump, it can be eliminated by adjusting the pressure of the sealing chamber, and the pressure regulation of the sealing screw chamber is a very important link in the maintenance of the sealing of the plastic sheet melt pump. There is a pressure sensor in the screw cavity, which can measure the pressure difference between the screw cavity and the pump body. Its pressure value is set at 100-300 kPa. Normally, after the pressure is adjusted in place when driving, it is not necessary to regulate in daily maintenance work. Zhengzhou Bate professional melt pump manufacturing enterprises provide melt conveying equipment including rubber extrusion melt pump, corrosion resistant polymer melt pump, PVC sheet melt pump, etc.

pre:Performance Advantage of Melt Pump for Casting Film

next: Reasons for Fracture of Pump Shaft of Single Screw Special Melt Pump