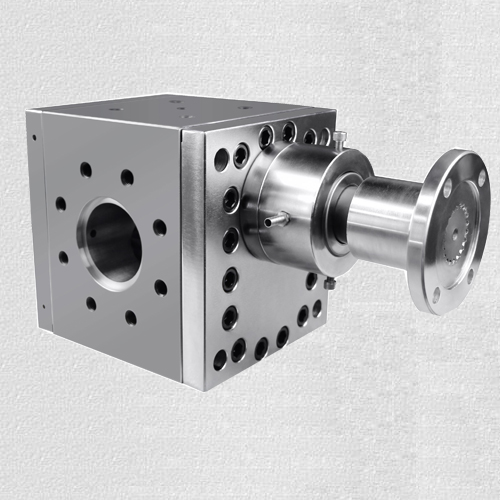

Batte's well-known gear pump manufacturers have many years of experience in R&D and production of gear pump equipment. The gear pumps provided have the advantages of simple structure, high cost performance, resistance to pollution, good suction performance under high viscosity, and easy operation. The Zhengzhou gear pump manufacturers will describe the bearing materials and structure of the gear pump.

The new generation gear pump provided by Zhengzhou Bart usually uses sliding bearings. The spiral flow path is designed on the non-load bearing surface of the bearing inner wall. The spiral rotation is the same as that of the gear shaft; the outer end of the bearing communicates with the liquid inlet of the gear pump. The spiral groove on the inner end of the bearing is in communication with the root of the gear tooth (vacuum position) that just disengaged from the gear. When the gear pump shaft rotates, the cryogenic liquid is sucked into the bearing through the spiral action and the pressure difference between the two ends of the bearing, and then flows into the newly disengaged tooth to form a self-priming low pressure lubrication system with sufficient lubrication and rapid heat dissipation.