Zhengzhou batte Specialized Melt Pump Manufacturing Co., Ltd. has many years of melt gear pump processing and production experience, providing professional melt pump equipment including: pipe melt pump, PVC special melt pump, low viscosity material melt pump, etc., to meet the production requirements of different fields; Haike provides high standard, high performance melt pump, favored by the market; Surface Zhengzhou batte introduces the application field and performance advantages of melt pumps for low viscosity materials.

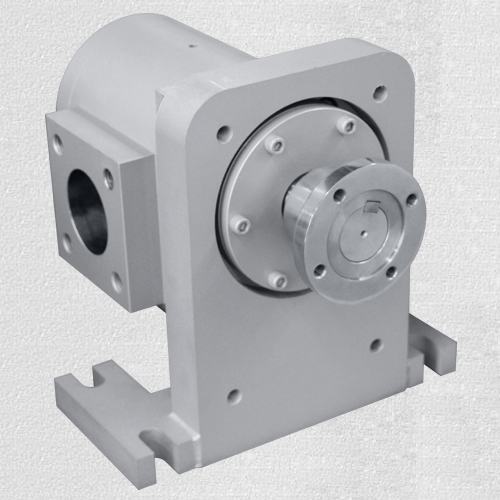

In the field of plastic extrusion, there are a large number of low viscosity melts that need pumps to transport; Haike aims at this situation, and the research and development of low viscosity materials with melt gear pumps, very good to meet the needs of market users; such as the chemical industry in the raw liquor, solution, glue, esters, oligomers, prepolymers, and so on, a variety of pharmaceutical, fuel, oil, dyeing and dyeing. Materials, coatings, lubricants and other materials. The viscosity of the low viscosity melt gear pump is about 0.3mPa.s to 1000mPa.s. The heating mode of low viscosity melt pump can choose full jacket, electric heating, non-heating and so on according to the nature of conveying materials; the sealing structure of low viscosity melt pump can choose melt dynamic seal + packing seal, or mechanical seal, or high temperature resistant packing seal, etc. Its gears and bearings are all made of wear-resistant corrosive materials, such as nitriding steel. Tool steel, stainless steel, corrosion resistant alloy and so on.

pre:Melt pump improves product dimensional accuracy effectively

next: Tight melt pump provides power for extrusion production line