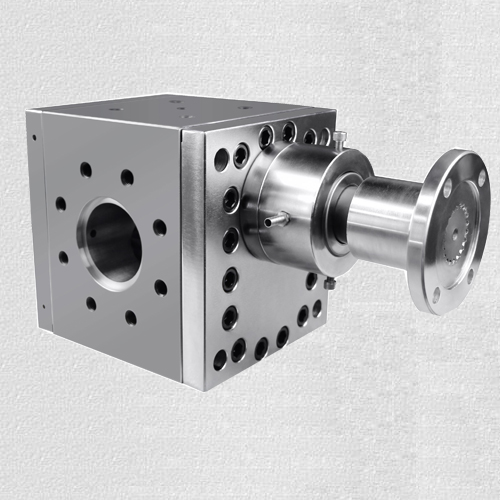

The manufacture of stable and accurate melt pump has been a sincere discussion and research direction, because high-precision melt pump extrusion production line is an indispensable link, and to a certain extent, for the stable performance of the extruder play a pivotal role in the production of qualified quality products.

The melt pump provides the necessary system pressure for the die to enhance, improve and stabilize the efficient extrusion of plastic materials, thereby improving the efficiency of the production line and producing the best end products. After the melt pump is installed, the maximum pressure of the extruder is behind the pump, which can reduce the pressure in the extrusion line, the shear strength of the melt, the temperature curve is gentle, and the temperature rise is reduced. It also plays an effective buffer role to the unstable melt fluctuation pressure coming from the pump, making the pressure peak value and pulse can be smoothly or even completely eliminated, creating a stable pressure production environment.

The key component of the melt pump, the gear, is the guarantee of effective measurement and pressurization. The melt pump equipped with the sincere die breaks through the study of the fine wear changes between the gears. The Swiss precision technology of stabilizing pressure is introduced into the research and development of the product in the rotating gear and self-lubricating bearing, which provides a more stable extrusion line. Fixed and long-term production guarantee.

pre:Application fields and advantages of melt pumps for low viscosity materials

next: How does the melt pump improve the efficiency and accuracy of extrusion molding