The following batte Zhengzhou melt pump manufacturers, on the specific analysis of the daily use of melt supercharging pump matters needing attention.

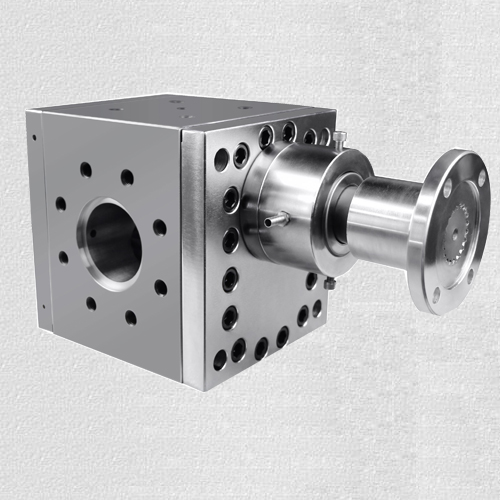

The driving power of the melt pressurized pump with variable frequency speed is still a fluctuating range because of the daily frequent spinning and stopping operation of the pump. It is not an ideal stability value, which is a constant impact on the bearing and gear bearing of the mechanical part. The service coefficient of the type selection of the gear box and the universal coupling of the booster pump is larger than that of the general machine. It is usually used by 2.5-3.0; the selection of 1.6-2.0 can also be used. In order to cope with the state of high productivity, the reliability of the equipment is lower, and the power of the motor is generally compared to the supercharging. The maximum power load of the pump is 50%.

It is necessary to consider the design of the ventilating and cooling of the booster pump gear box, the universal coupling and the motor, in order to ensure the reliability of the equipment lubrication, especially in the summer high temperature environment, especially in the summer high temperature environment. The poor lubrication of the sliding bearing of the melt pressurized pump also leads to the increase of the driving power, but only 2%-3% is increased at most; the serious lubrication problem will directly cause the accident of the pressure pump bearing to bite and stop.